MAIN ADVANTAGES:

EASE OF USE

- Independent units.

- Removable basket with quick release mechanism.

- Automatic stop.

- Simple installation.

CONFIGURABLE

- Centrifuges with different removable baskets for appropriate unloading processes.

- Numerous application areas:

- for parts and/or filings

- for deoiling, washing, spinning, drying

- Stainless steel version for use in the food industry.

RELIABILITY

- Heavy masses to minimize vibration.

- Three-point suspension for greater stability.

- Limited maintenance.

TYPES OF CENTRIFUGES

KC TYPE

- Handles attached to the top of the basket (∅ 400 and 475 mm).

- Pins placed on the outside of the basket to which the handling element can be attached.

- Special top ring for robot operation.

- Unloading by tipping.

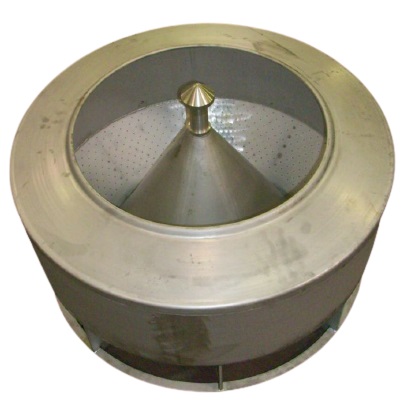

KFO TYPE

- Operation via central cone.

- Unloading by opening 2 double lower doors.

KFE TYPE

- Operation via central cone.

- Unloading by moving the extendable cone downwards after placing the basket on the unloading platform.

MAIN FEATURES

- Centrifuge with rigid structure (RC) or suspended on three points (SA and SC).

- Basket driven in rotation by direct axial motor (SA) or side mounted motor and belt drive (RC and SC). Fixed or variable speed by inverter (Vx).

- Counter-current (SA) or disc (SC) braking for single-speed centrifuges; Inverter and resistive braking for variable-speed centrifuges.

- Construction materials: cast iron and carbon steel in standard versions. Possibility of making some or all parts in contact with the product from acid-resistant or coated steel.

- Manual opening/closing of the lid or automatic using pneumatic lifters.

- Heating device (C2) integrated with the cover or independent, depending on the model and required power (1400 W - 12 kW). Possibility of supplying a thermoregulator.

- Ability to process components with retention zones in a basket with a conical base, connected to an alternating clockwise/counterclockwise drive, facilitating liquid drainage and component drying.

- Specially designed baskets: divided, with internal compartments, for crates, buckets or rectangular boxes, with flat or perforated base plate

- Special basket perforation or appropriate filter mesh or removable bag.

- Special compartment baskets and filter aids, i.e. filter bags.

- Independent control panel or control board with timer to adjust cycle times.

- Possibility of equipping the centrifuge (RC and SC types only) with explosion-proof equipment in accordance with European or American electrical standards.

ATEX compliance for European markets.

TECHNICAL CHARACTERISTICS

| Type | Bin | Bin | Bin | Bin | Bin | Bin | Bin | Bin | Dryer | Heating device (C2) | Heating device (C2) | ||

| Model | Diameter mm | Height mm | Total capacity L | Usable capacity L | Max. load kg | Weight with empty basket kg | Rotational speed rpm | Weight kg | Power kW | Fan kW | |||

| SA 40 | CC | 400 | 250 | 28 | 15 | 30 | 8 | 750 | 200 | 1,4 | 18 | ||

| SA 50 | CC | 475 | 280 | 45 | 30 | 60 | 11 | 750 | 300 | 1,4 | 18 | ||

| SC 70 Vx | CC | 675 | 365 | 100 | 60 | 120 | 40 | 850 | 600 | 3 | 125 | ||

| SC 85 Vx | CC | 800 | 380 | 155 | 85 | 150 | 53 | 650 | 1200 | 4 | 125 | ||

| SC 85 Vx | KFO | 850 | 470 | 225 | 150 | 180 | 70 | 650 | 1300 | 4 | 125 | ||

| SC 85 Vx | KFE | 850 | 390 | 160 | 100 | 180 | 90 | 650 | 1400 | 4 | 125 | ||

| SC 100 Vx | CC | 1000 | 450 | 290 | 150 | 220 | 85 | 600 | 1500 | 6 | 125 | ||

| SC 100 Vx | KFO | 1000 | 500 | 340 | 200 | 240 | 90 | 650 | 1600 | 6 | 125 | ||

| SC 100 Vx | KFE | 1000 | 455 | 250 | 150 | 240 | 120 | 650 | 1700 | 6 | 125 | ||

| SC 120 Vx | CC | 1200 | 460 | 460 | 220 | 300 | 135 | 550 | 2000 | 6 | 125 | ||

| SC 120 Vx | KFO | 1200 | 600 | 600 | 310 | 370 | 110 | 500 | 2100 | 6 | 125 | ||

| SC 120 Vx | KFE | 1200 | 500 | 440 | 230 | 370 | 150 | 550 | 2200 | 6 | 125 | ||

| SC 150 Vx | KFO | 1500 | 600 | 900 | 410 | 500 | 155 | 500 | 3500 | 6 | 125 | ||

| RC-Vx | CC | Models available in basket ∅: 400, 475, 600, 675 mm and more.Their characteristics depend on the choice of ROUSSELET ROBATEL according to the use and the product concerned

|

|||||||||||