PRINCIPLE OF OPERATION IN A FULLY AUTOMATED PROCESS

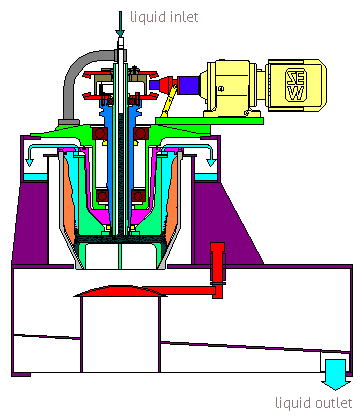

Power/Spin

- The suspension is fed via a rotating disc that rotates at the same speed and direction as the bowl (minimized turbulence)

- Under the influence of centrifugal force (1,500 to 2,200 x G), the denser solid particles migrate to the walls of the bowl and accumulate, forming a "dough". Rotating baffles divide the bowl into four "quiet" zones and ensure that the slurry has the same rotational speed as the bowl wall, ensuring faster/more efficient separation.

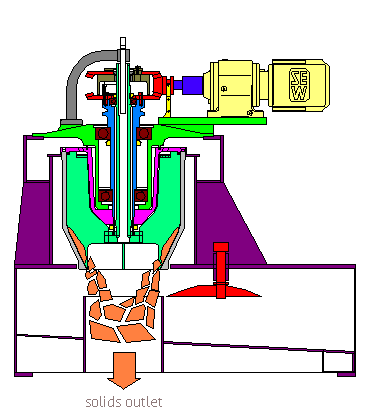

Sludge unloading

- A special device detects the effective mass of sediment inside the bowl. This patented system has the following advantages:

– optimized bowl filling,

– does not depend on changes in the feed flow rate or sludge concentration, allows you to avoid overfilling and premature mechanical wear.

- Once a certain sludge mass is reached, the supply is automatically cut off. The lower bowl flange and baffle assembly are set to low rotation speed in opposite directions, and the bowl rotation speed is changed several times. The baffles become a scraping device and remove solids from the bowl walls, allowing them to drain by gravity through the bottom of the bowl and through a pneumatically actuated anti-drip gutter.

MODEL TABLE

| MODEL | DRC30VxBO | DRC45VXBO | DRC45VxBO

|

| Diameter (mm) | 300 | 450 | 450 |

| Total capacity (Litres) | 15 | 48 | 67 |

| Sludge Capacity (Liters) | 8 | 16 | 23 |

| Rotational speed (rpm) | 3000 | 2500 | 2500 |

| G-force (xa) | 1510 | 1570 | 1570 |