AVAILABLE IN TWO UNLOADING VERSIONS:

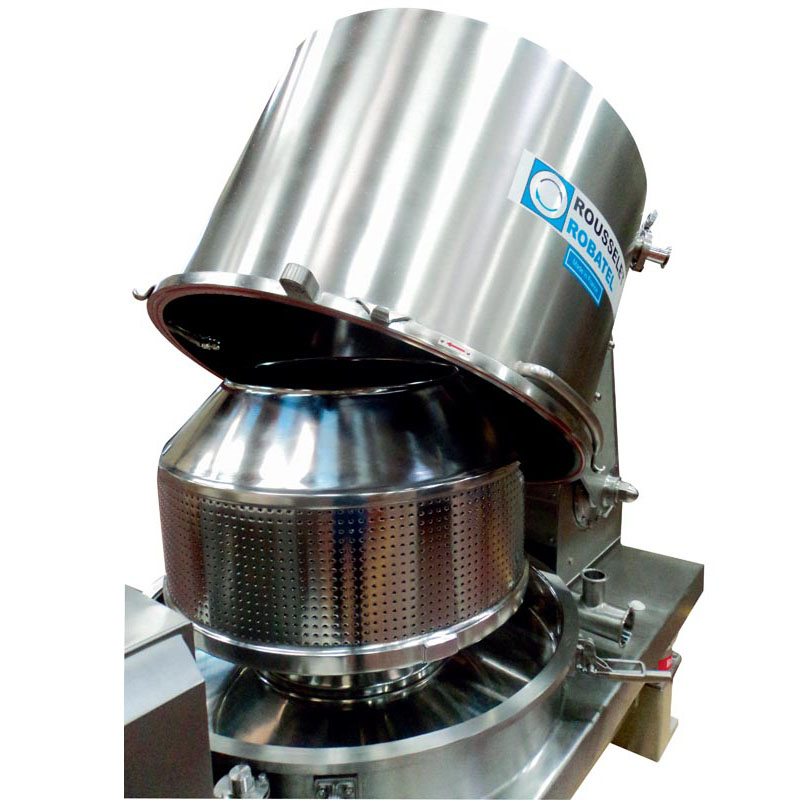

– Manual removal (using a dustpan): RC models

– Semi-automatic, removable filter bag model RC-KS

Various auxiliary options in this basket centrifuge model:

– Quick basket release

– Interchangeable set of decanting tools to change between filtration and decanting methods (only for RC 40 and RC 50 models)

– Fully openable housing

– Filter bag extraction system (KSA models) or quick release basket for removal

RC-Vx.R

RC-Vx.R with fully openable housing

TECHNICAL CHARACTERISTICS

BASKET TYPE (Data Max.)

| MODEL | ∅ mm | Height mm | Usable capacity dm3 | Load kg | Filtration area m2 | Rotation speed rpm | G-Strength |

| RC 40 | 400 | 250 | 20 | 25 | 0.31 | 3000 | 2010 |

| RC 40 KSA | 400 | 280 | 18 | 22.5 | 0.31 | 2300 | 1180 |

| RC 50 | 500 | 320 | 34 | 42.5 | 0.50 | 2250 | 1410 |

| RC 50 KSA | 500 | 320 | 35 | 43 | 0.50 | 1700 | 810 |

| RC 60 | 600 | 330 | 55 | 68.5 | 0.57 | 1800 | 1090 |

| RC 50 KSA | 600 | 305 | 60 | 75 | 0.57 | 1500 | 750 |

SIMPLIFIED VERSIONS

– Models of the SA… series with a directly coupled axial motor

· Centrifuges that cannot be delivered in an explosion-proof version, with use limited to liquid processes

· Direct coupled motor and electric braking

· Triple Suspension

TECHNICAL CHARACTERISTICS

| MODEL | ∅mm | Height mm | Usable volume dm³ |

Load kg | Rotational speed rpm |

| SA 40 | 400 | 250 | 15 | 18 | 1500 |

| SA 50 | 500 | 280 | 30 | 37 | 1500 |

AVAILABLE OPTIONS

· Various construction materials

· Speed adjustment

· Increased top speed

· Feeding and washing pipes

A VERY LARGE SELECTION OF TECHNICAL CHARACTERISTICS, OPTIONAL AND AUXILIARY DEVICES TO CUSTOMIZE BASKET CENTRIFUGES TO YOUR SPECIFIC PRODUCTION NEEDS

Rigid base plate mounted on vibration dampers (VISCO type springs and dampers for scraper centrifuges)

· Centrifuge and auxiliary equipment installed on the bottom plate, portable frame, or mobile trolley (depending on weight) made of painted carbon steel or acid-resistant steel.

· Side-mounted electric motor with speed regulation via an inverter and transmission via antistatic transmission belts.

· Watertight or explosion-proof electrical equipment mounted on the centrifuge in accordance with European standards EN 60079… (ATEX compliance for the EU) or with North American standards

· Independent control panel, installed outside the process zone at the centrifuge in an explosion-proof housing

· Gas-tight construction for operation under the protection of inert gases

· Stainless steel construction or other materials (alloy steels, titanium…) or coatings (Halar, special rubber…) for some or all product contact parts.

· Various degrees of polishing and surface electropolishing available

· Large selection of sealing materials (Neoprene, Ethyl Propylene, Viton, Silicone, encapsulated PTFE…) and various filter media (polypropylene, polyester, polyamide, cotton…)

· Feeding, washing and outlet pipes available with flange connections (other process connections and fittings on customer request)

· Panoramic sight glass with wiper. Additional sight glasses with or without lighting lamp.

· C.I.P. system

· PLC control for automatic cycle control (for scraper basket centrifuges)

Nitrogen shield, pressure control or oxygen content control, hydraulic shield…

Dough detector (for basket diameters of 500 mm and larger)

· Unbalance switch or vibration monitoring control

· Separation of process and technical zones to prevent contamination

AUTOMATIC BASKET CENTRIFUGES WITH SOLID BODY UNLOADING USING A SCRAPER

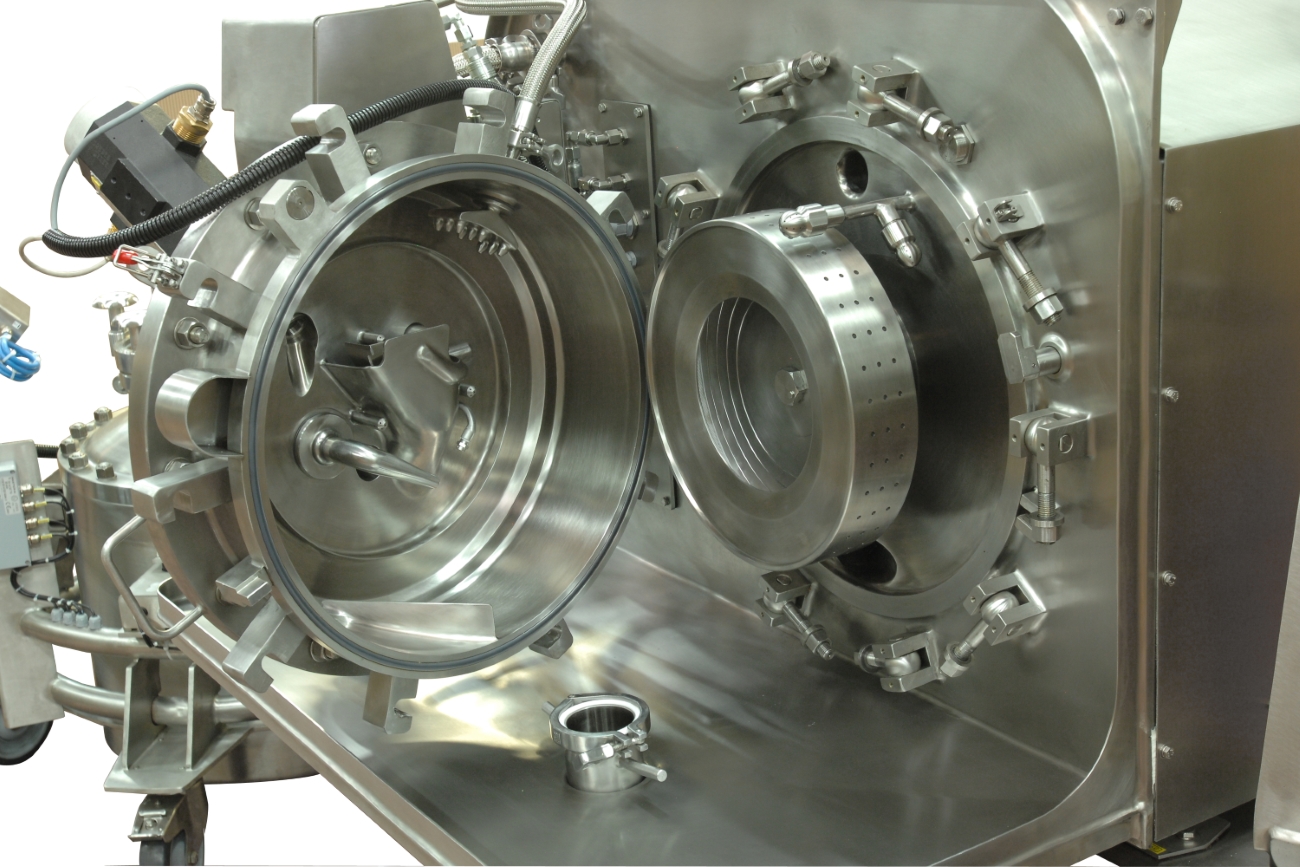

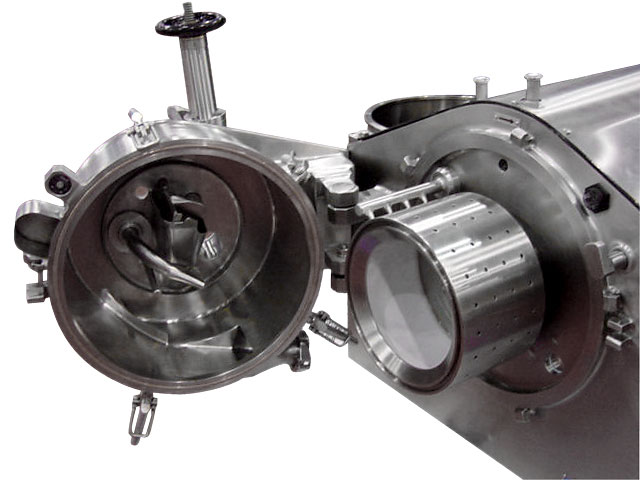

Available in two versions:

On a horizontal axis with unloading of solids through an inclined unloading pipe,

With a vertical axis with discharge of solids through the holes in the bottom of the basket.

EHBL-DRG RC-Vx DEC.

TECHNICAL CHARACTERISTICS

| MODEL | ∅mm | Height mm | Usable volume dm³ |

Load kg | Rotational speed rpm | Centrifugal Force G |

| EHBL 303 | 300 | 75 | 2.9 | 3.6 | 3500 | 2050 |

| EHBL 503 | 500 | 250 | 24 | 30 | 2600 | 1890 |

| EHBL 633 | 630 | 315 | 40 | 50 | 2400 | 2020 |

| RC 63 Vx DEC | 630 | 170 | 50 | 62 | 1500 | 790 |

· Hydraulic scraper blade activation (or pneumatic oil cylinder on smaller models).

cGMP execution, the possibility of installation in a cleanroom for centrifuges with a horizontal axis.

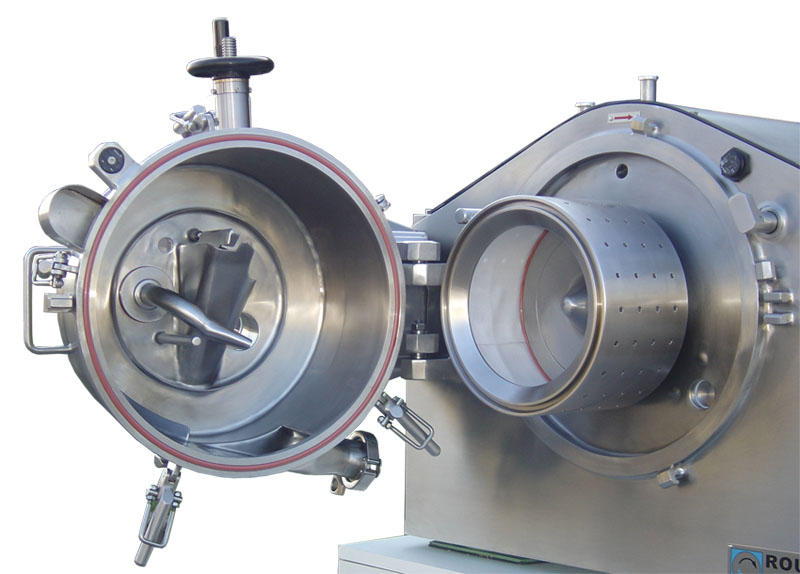

VERTICAL AXIS DECANTATORS

– DRC 40 / 50 / 60 MODELS

Three models, with highly effective separation due to the generated very high centrifugal force, one of the highest available on the market.

Liquid drainage: via skimmer pipe(s) or overflow.

Solids unloading: manual or via skimmer tube

· The bowl can be produced with or without deflectors.

· GMP execution: fully openable housing, easy-to-clean flat bottom bowl, retractable skimmer, CIP system….

· Mounting on the frame for easy movement.

· Many options available, similar to those previously mentioned for filter centrifuges.

· Filter kits available with perforated basket and flushing tube (only for the smallest models/reduced speed).

TECHNICAL CHARACTERISTICS

| MODEL | ∅mm | Height mm | Usable volume dm³ |

Load kg | Rotational speed rpm | Centrifugal Force G |

| DRC 40 | 400 | 280 | 18 | 22 | 3500 | 2740 |

| DRC 50 | 500 | 320 | 40 | 50 | 2750 | 2110 |

| DRC 60 | 600 | 350 | 60 | 75 | 2600 | 2270 |

These technical characteristics are defined exclusively by Rousselet Robatel, in accordance with the intended use and specifications of the products processed

DRC-Vx

RC-Vx.R

Special version: decanter centrifuge with discharge of solids by means of a scraper and 45° axis

Special version: two-part trolley