Main features of SCPC-TE centrifuges:

Ease of use

- Space optimization compact unit; SCPC-TE type only requires small space due to the closed and continuous process, the working environment of the centrifuge can be simplified.

- Limited maintenance. Replacement of spare parts is not necessary frequently because imbalance is kept to a minimum. This is due to the even and regular feeding of the product into the rotating basket. Also, because the machine is not started and stopped frequently, the level of imbalance is significantly reduced.

Quality

- Continuous extraction by working on a thin layer of fibers, the centrifuge allows us to obtain a uniform degree of dehydration.

Productivity

- Continuous loading and unloading of fibers enables the highest possible efficiency to be achieved.

MAIN CHARACTERISTICS

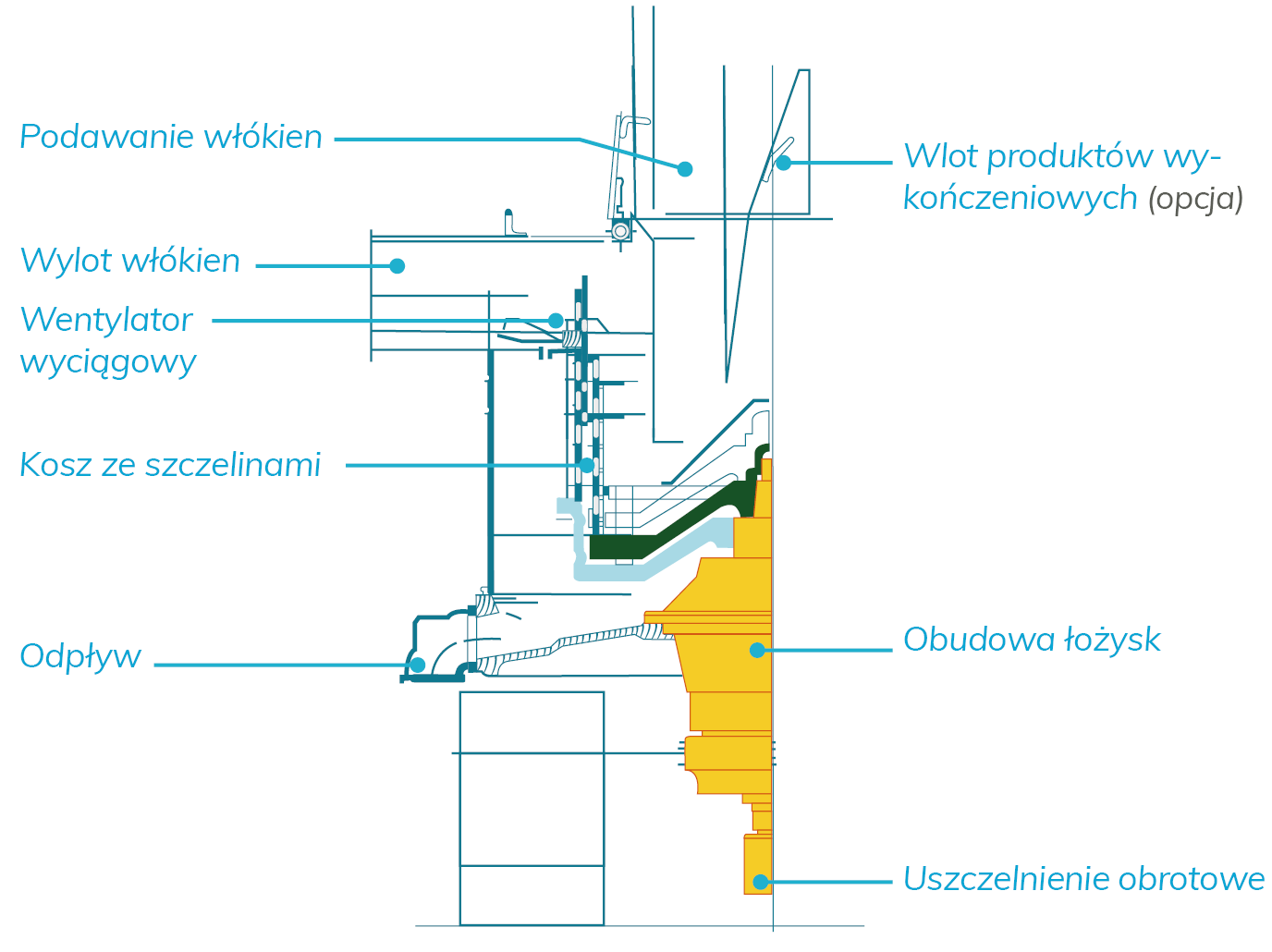

- The interior of the two-stage basket is equipped with vertical slots.

- The lower stage works as a pushing plate and has an alternating up and down movement using a hydraulic device.

- In this way, the material that we want to process is continuously fed into the basket and set in rotation, and the up-and-down movement causes the centrifuged product to be pushed upwards in accordance with the frequency of the up-and-down movements of the pusher (pusher plate)

AUXILIARY DEVICES AND OPTIONS

- Version made entirely of acid-resistant steel for work with corrosive products (e.g. carbonization industry).

- Fully opening lid for full access to the basket allowing for quick and easy cleaning when needed.

- Selection of the size of the filter media slot openings, which can be selected according to the size of the fibres (e.g. in the floss fibre industry we have a very small filter media slot, while in wool fibres the slot is larger).

- Speed control via hydrostatic transmission or inverter.

The goal is to optimize extraction while fully taking into account the characteristics and structure of the fibers.

TECHNICAL CHARACTERISTICS OF THE SCPC-TE CENTRIFUGE SERIES

| Model | Diameter mm | Rotation speed in rpm | Engine power kW | Engine power kW | Dimensions L x W x H mm | Total weight kg | Dry product capacity per hour kg | Dry product capacity per hour kg | Dry product capacity per hour kg |

| Centrifuge | Hydraulic unit | Synthetic | Wool | Cotton | |||||

| SCPC 120TE | 900 | 950 | 15 | 4 | 2100x1930x2500 | 3060 | 1000 > 1600 | 800 > 1200 | 450 > 700 |

| SCPC 150TE | 1200 | 850 | 30 | 11 | 270x2320x2740 | 5920 | 1400 > 2000 | 1200 > 1800 | 700 > 1200 |