TYPICAL APPLICATIONS

- Animal products: Processing of fish and animal products.

- Plant-based products: vegetables, alcohol, algae.

- Agricultural products: pharmaceutical, chemical, textile, energy.

- Dehydration of whole or sliced fresh fruits and vegetables after washing, aromatic herbs before deep freezing, vegetables after blanching or before freeze-drying, food products used for decorating products garnished, garden seeds and marine products (seaweed, fishmeal and derived products).

- Essential oil extraction/removal.

- Starch dehydration.

- Extraction / removal of tallow in the waste disposal industry from the food industry, honey from honeycombs, excess oil from fried products (bread croutons, onions, walnuts), syrup from candied fruits, vegetable oil from fruit seeds, juices or syrups from the peel of fruits or plants in alcohol.

- Clarification of fruit juices and animal fats.

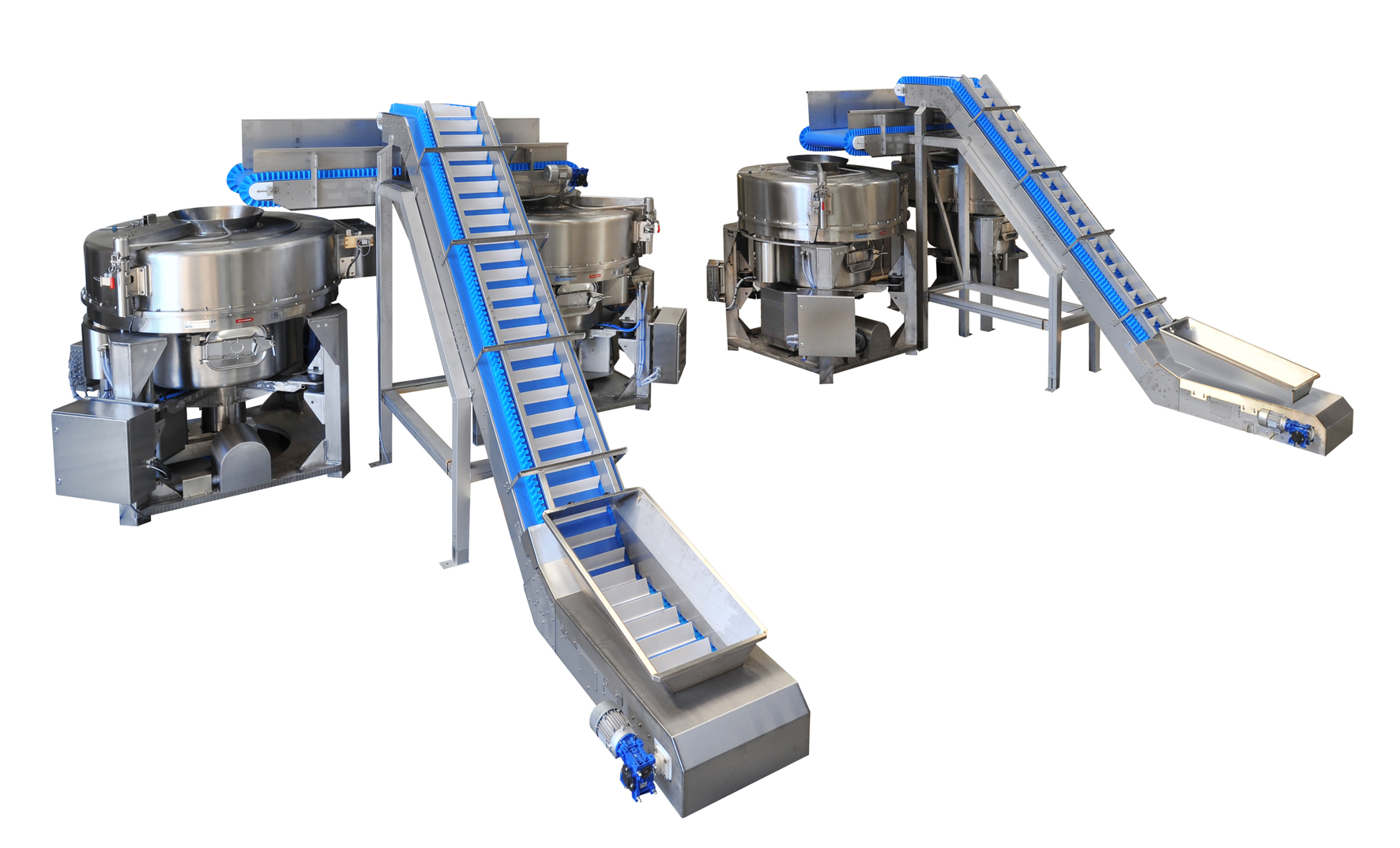

RCPC-VX BASKET CENTRIFUGE SERIES

The RCPC-VX range of fully automatic centrifuges has been designed specifically for processing fragile or delicate food products.

This basket centrifuge has a very compact design. In these machines, it is possible to adjust the discharge point of the centrifuged product, which significantly facilitates the integration of these basket centrifuges with existing technological lines.

MAIN FEATURES OF RCPC-VX BASKET CENTRIFUGES

EFFICIENCY

- From 350 kg to 3600 kg per hour, depending on the centrifuge model, product parameter characteristics, e.g. size, density, brittleness and moisture target.

- Rotation speed adjustable by using an inverter to select the most optimal basket speed for each phase of the spin cycle and in order to appropriate adjustment of times acceleration and braking of the centrifuge. Cycle programmer enabling saving to 19 different cycles.

- A control panel that can also control auxiliary devices (e.g. pumps or conveyors) located in front of and/or behind the device.

AVAILABILITY / EASY TO CLEAN

- Fully opening cover, wide inspection door, hopper cover discharge.

- The base of the basket is made of solid acid-resistant steel. Basket walls made of trapezoidal wires, CIP pipes, casing without structure places where residues accumulate product.

SECURITY / RELIABILITY

- The cover and inspection door can be only open when zero basket speed is indicated.

- Anti-vibration pads and Engine counterweights ensure high stability of the centrifuge.

- The design of the centrifuge is in accordance with safety regulations and European standards.

APPLICATION RANGE OF RCPC-VX CENTRIFUGES

- ABOUTdehydration of whole, cut or chopped fresh vegetables after washing or before dressing (leaf salads, vegetable salads, soybeans, potatoes…).

- Dehydrating food products after blanching (spinach leaves…) or after cooking (rice…).

- Dehydrating fresh aromatic herbs before deep freezing.

- Dehydrating delicatessen garnishes.

- De-oiling/degreasing food products after frying (bread croutons, bacon bits, walnuts…).

The most important feature of this type of centrifuge is its basket loading/unloading mode. The basket consists of two independent parts:

- Pbasket pressure plate (so-called pusher plate) rotates at the same speed like a basket and moves up and down down the entire height of the basket.

This design solution enables:

- Even distribution of products in the whole basket that is created during downward movement of the pressure plate during work.

- This creates a thin and even layer of products over the entire surface. filter basket, allowing the removal centrifuged product from the basket through a pressure plate that ejects the product on the rotating top ring, which then transfers the product to the chute unloading

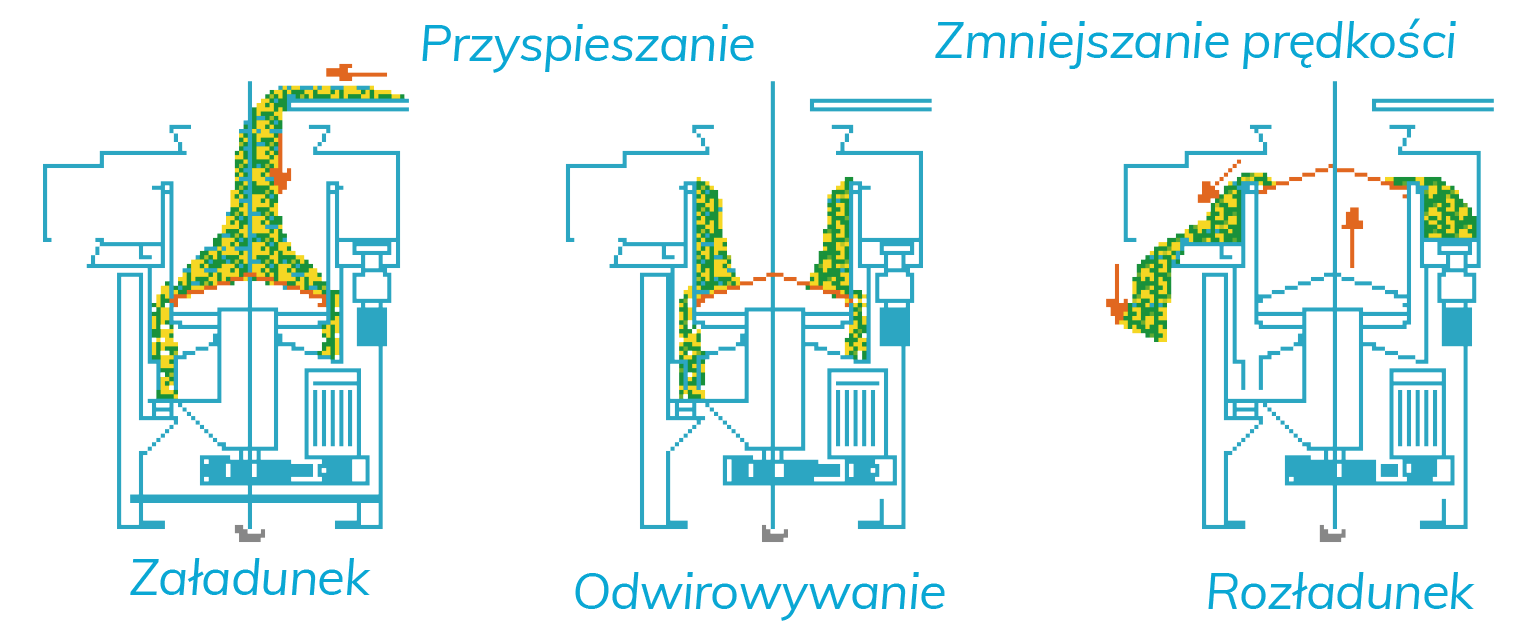

CYCLE DESCRIPTION

The basket rotation speeds and duration of each spin stage can be adjusted independently:

- Administration product through the funnel which is located above cover, with the basket running at low speed.

- Acceleration – The basket speed is increased according to the desired speed for a specific assortment products.

- Spinning for a specified period of time.

- Unloading – The pressure plate moves upwards allowing the product to be discharged from the basket without damaging it and to be collected on the rotating top ring before being discharged through the discharge chute

TECHNICAL CHARACTERISTICS

| MODEL | Basket diameter mm | Basket height mm | Maximum basket speed rpm | Centrifuge motor power kW | Dimensions LxWxH m | Weight kg |

| RCPC 70 Vx | 700 | 525 | 630 | 9 | 1.580x1.380x1.82 | 1750 |

| RSCPC 120 Vx | 1000 | 660 | 630 | 15 | 2,280x1,970x2.17 | 3150 |

ADDITIONAL AND OPTIONAL EQUIPMENT

- Coating contact parts and places of the device in contact with the product with special coatings (e.g. dispersion coatings).

- Adjusting the ring unloading speed upper.

- Specially designed frame with two product outputs.

- Rotating washing heads placed on centrifuge lid.

- Programming of cycles and stages by PLC control. Monitoring of centrifuge vibrations.

- Control cabinet made of steel acid-resistant

- Feed conveyors and unloading