Past/Present/Future

Grinding over the years

In the past, a simple and economical method was to grind the grain using two rough stones, one of which was operated manually using hydraulic, animal or electrical power. This method resulted in the production of flour that was flaky and somewhat coarse. Sifting removes some of the bran, but the flour is still "blended", that is, it still contains some bran that is too finely ground to be removed.

Today

In 1830, an engineer from Zurich named Müller (in Polish the name translates as "Młynar"), who came up with the idea of replacing millstones with metal rollers during a discussion with his dentist, a roller mill (roller grinder) gently and sequentially crushes grain , while between each serving it is sifted in a new pair of rollers, and thus a very nice and smooth flour is obtained. There are actually 6 to 18 pairs of rollers, some corrugated and others smooth, with multiple screens and pneumatic or bucket conveying systems. It is very complicated, and this method, due to automation and its constant evolution, is not the best example of a rational solution. In addition, raw material losses are significant and the process, due to its complexity, requires highly skilled personnel for operation and maintenance.

Its weak point is the loss of sensory properties of the materials due to multiple passes in conveyors, sieves and installations that are almost never cleaned, resulting in material contamination.

In the future

Most grain mills will continue with this rotary roller milling technology, even though other new technologies are already available and breaking through. In fact, the patent, filed in 1894 and never used, was updated at Orbe in 1997. This process was described in the Ader organization's book "Energy in the Future."

Milling, called "F10 flour", shows that high-quality flour with the highest efficiency can be produced with a 10-fold reduction in energy consumption.

At the Wheat and Bread Museum in Echallens, this F10 flour has been tested on about thirty types of breads and pastries. Users of this flour have described this type of flour as excellent and easier to work with than traditional flour.

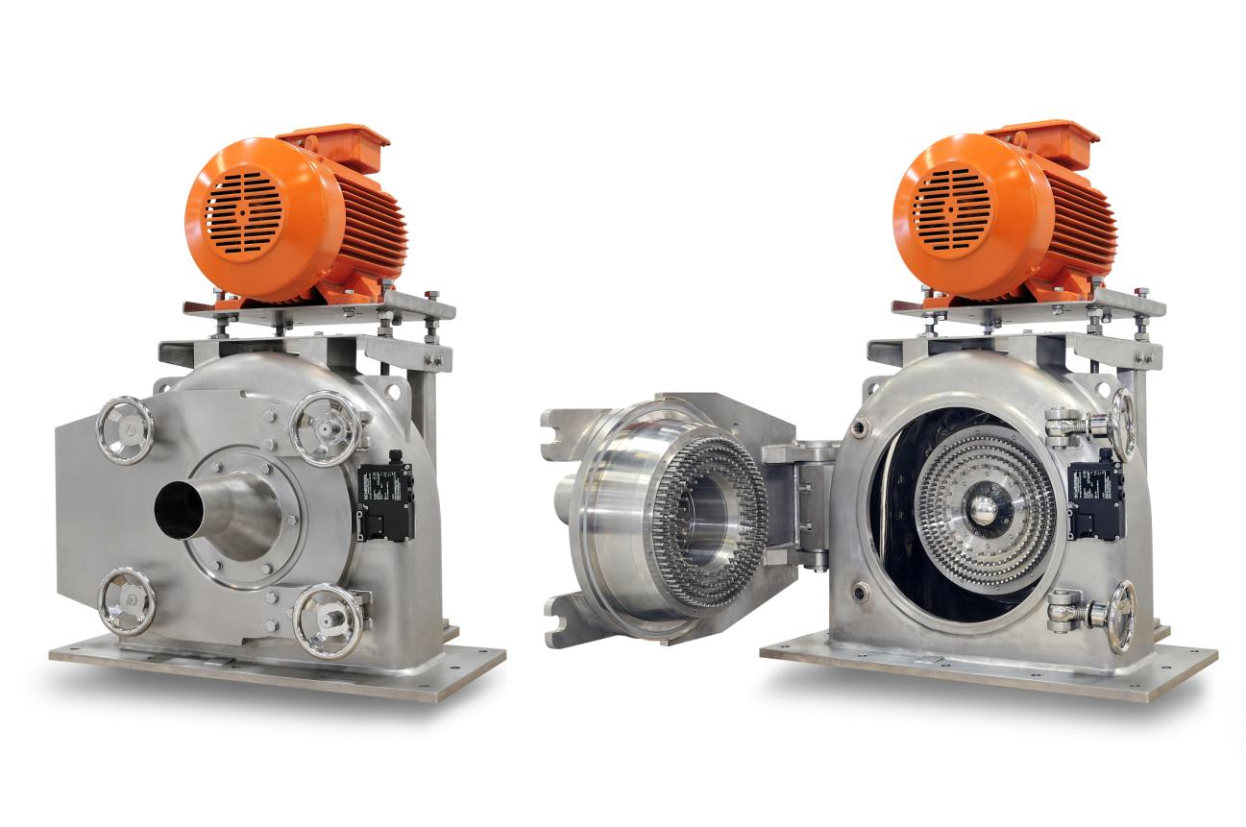

F10 grinding principle

The special feature of this mill is its simplicity. Only one grinding using a high-speed mill, approximately 10,000 rpm, followed by single sifters is enough to obtain high-quality flour, with excellent parameters, very clean bran and no industrial taste. This mill called "Multi-Pin” has been used for a long time for a wide range of grinding, especially to obtain very fine powders such as sugar powder and a wide range of chemical, food and pharmaceutical products. It consists of several rows of stator fingers (pins) and a second movable disc (the so-called rotor) rotating at high speed. The wheat grain passes into the grinding chamber, it is not crushed, it is tamped as it passes through various rows of fingers (pins). The transmission speed is approximately 130 meters per second.

The essence of this process is fine grinding of the wheat kernel, without breaking the bran. Bran has characteristic properties, namely, if it is very moist, it becomes very soft and behaves like rubber, so it does not crack when passed between fingers. Therefore, you should quickly wet the surface of the grain for a few minutes before grinding. The inside of the grain is not excessively soaked and allows for grinding. Therefore, only one pass through the mill and one sieving is needed to separate the bran. By changing the diameter of the grids, you can obtain different types of flour: bran, semi-white, white. It is also possible to produce whole meal without sifting, which further simplifies the process. Another interesting fact is that this method allows the production of very small batches, from several kilograms per hour to several tons if necessary. This is possible thanks to the easy expansion of the system, which is not possible in a traditional mill.

Advantages:

– The same installation can be used to grind wheat DURUM without any additional installation.

– Using the same mill, the flow rate can be easily adjusted.

– In the case of quite large flows, it is enough to adapt the multi-finger mill by choosing a machine with a different impeller diameter. This is possible because the process is scalable, which is not the case with lines with mills.

– Guaranteed elimination of insects that may be present in wheat.

– No mechanical or industrial tastes or odors.

– Very clean bran, no kernel residue.

– Significant reduction in energy consumption – up to 10 times less!

– Easy to use and no need for highly trained service staff.

– Grinding all types of grains.

– Possibility to grind small quantities and for small plants.

– An opportunity for farmers or traditional mills to diversify.

– Establishing a cooperative for the production of poppy seeds facilitates the organization of work and the financing of the line.

– Installation does not take up much space.