Advantages

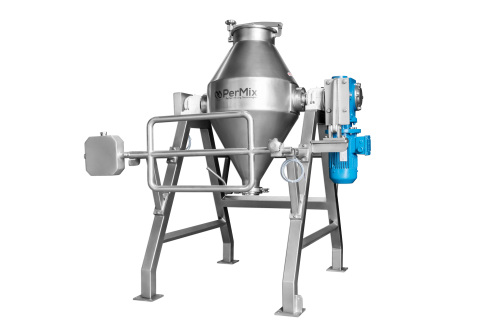

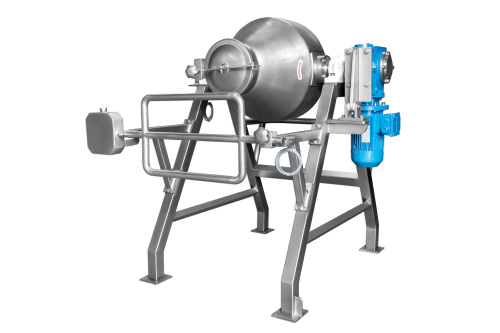

Compared to other types of mixing equipment, the PerMix Model PDC Double Cone Mixer provides the following benefits:

– Minimized material distortion due to the absence of any moving blades

– No contamination thanks to the closed area in the acid-resistant steel chamber

– Particularly suitable for mixing powders or granules that are temperature-sensitive, easily oxidized, crystallized, volatile, poisonous or have an irritating odor

– Many options are available such as side chopper, variable speed, automatic stop in unloading position, pneumatic valve, touch screen operation panel, safety barriers, etc.

Principle of operation

The PerMix PDC double-cone mixer has a chamber consisting of two cones. Powders and granules are fed into the double cone chamber manually or via a vacuum conveyor. The gear motor drives the chamber, rotating it 360 degrees. This multi-dimensional movement causes the powders and granules inside to spin up and down and collide with each other all the time, achieving uniform mixing action in a short time.

A safety barrier or housing is often mounted in front of or around a double cone mixer, providing a safety feature that operates on the principle that the mixer is immediately stopped when the barrier or housing is open and prevents the mixing chamber from operating when the barrier or housing is not closed. .

Features and options

The simplicity of the PerMix model PDC double-cone mixer design ensures low initial cost, easy maintenance and simple operation. Mixers of this type can be supplied with a variety of options, including but not limited to:

– Structure fully made of acid-resistant steel for hygienic requirements

– Internal shredders

– Version adapted for operation under vacuum / drying with a heating jacket, vacuum pump, dust filter, condenser, etc.

– Special spray nozzle

– Safety barrier

– Mobile trolley

– PLC control and touch screen

– Removable compartments

Application

PerMix PDC double-cone mixers are widely used in the processing of pharmaceuticals, dyes, plastics, resins, food products, ceramic glazes, metal powders, cosmetics, detergents, insecticides, explosives and many others:

– WITHfood

Breakfast cereals, Enzymes, Flavors, Herbs, Minerals, Nutraceuticals, Spices, Tea blends, Tobacco, Vitamin blends

– Chemicals

Agrochemicals, ceramic powders, detergents, medicines, dyes, leather aids, metal powders, pigments, plastic granules, plastic granules, plastic powders, textile aids

– Pharmaceuticals

Active substances, Biological solids, Carcinogenic substances, Concentrated active ingredients, Generics, Intermediate products, Sterile products, Toxic substances

Specifications

| Model | Total capacity, Liters | Working capacity, Liters | Engine power, kW | Length, mm | Width, mm | Height, mm | Working height, mm |

| PDC-5 | 5 | 3 | 0.25 | 800 | 500 | 660 | 750 |

| PDC-15 | 15 | 7 | 0.37 | 600 | 430 | 1,265 | 1,335 |

| PDC-45 | 45 | 20 | 0.55 | 850 | 620 | 1,540 | 1,650 |

| PDC-100 | 100 | 50 | 0.75 | 1,100 | 810 | 1,620 | 1,950 |

| PDC-200 | 200 | 100 | 1.1 | 1,400 | 1,020 | 2,100 | 2,280 |

| PDC-300 | 300 | 150 | 1.5 | 1,600 | 1,160 | 2,320 | 2,530 |

| PDC-500 | 500 | 250 | 2.2 | 1,630 | 1,070 | 2,600 | 2,600 |

| PDC-700 | 700 | 350 | 3 | 1,820 | 1,200 | 2,770 | 2,770 |

| PDC-1000 | 1,000 | 500 | 4 | 2,100 | 1,350 | 2,985 | 2,985 |

| PDC-2000 | 2,000 | 1,000 | 5.5 | 2,620 | 1,350 | 2,145 | 2,280 |

| PDC-3000 | 3,000 | 1,500 | 7.5 | 2,990 | 1,550 | 2,440 | 2,600 |

| PDC-4000 | 4,000 | 2,000 | 11 | 3,280 | 1,680 | 2,685 | 2,850 |

| PDC-5000 | 5,000 | 2,500 | 15 | 3,530 | 1,810 | 2,890 | 3,070 |

1. All specifications are as accurate as reasonably possible, but are not binding.

2. Custom sizes are available upon request.

3. PerMix reserves the right to modify the design without notice.