Process

The process begins by mixing the liquid or pasty product in the hegatec feed tank. The feeding pump ensures even distribution on the conveyor belt inside the dryer. There is a vacuum in the housing of the hegatec vacuum belt dryer. The operating vacuum is precisely controlled by the hegatec vacuum system. After the product is fed onto parallel belt conveyors, it passes through various heating zones and a final cooling zone. The hegatec integrated linear granulator grinds the final product. The required dry weight of the final product can be adjusted using adjustable parameters such as feed volume, transport speed, temperature and pressure.

BENEFITS

- gentle drying by lowering the boiling point

- continuous, automated process

- fast drying action

- low product temperature

- low aroma loss

- no oxidation of the product

- controlled Maillard reaction

- very good solubility of final products in water

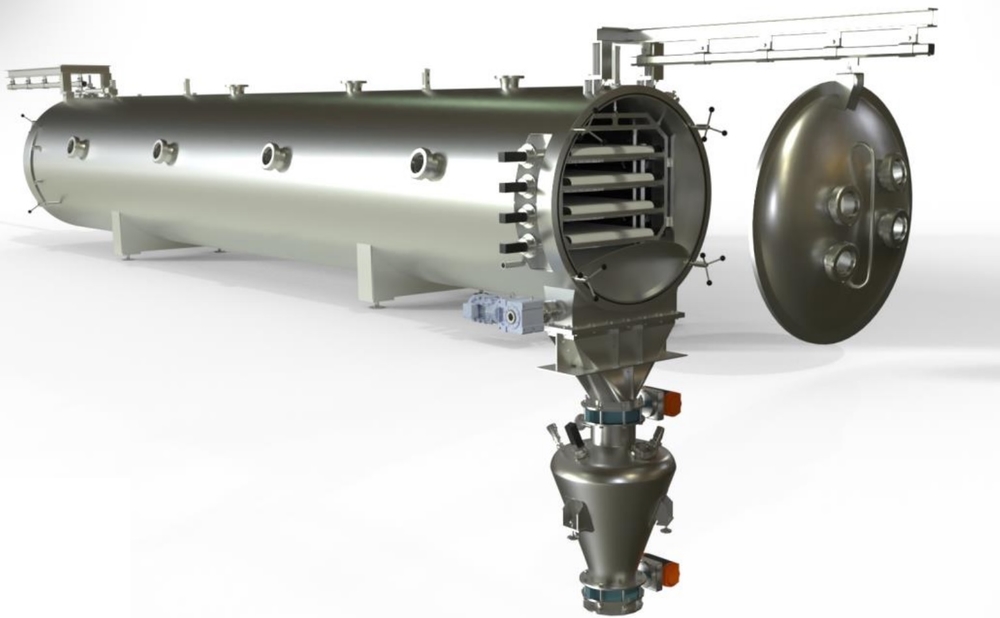

Vacuum belt dryer

SIZE DOES MATTER

The hegatec continuous vacuum belt dryer is used for the gentle drying of pasty and liquid products such as malt blends, meat extracts, herbal extracts, etc. The hegatec vacuum belt dryer is available in sizes ranging from laboratory to industrial. Based on accurate calculations, the hegatec vacuum belt dryer is tailored to the needs of your product.