ADVANCED SPICE STERILIZATION SOLUTIONS

PerMix, a company with extensive experience in the production of industrial mixers, presents an innovative spice sterilization technology: a dynamic steam sterilization system, specially adapted to the needs of the spice, herb and ground spice industry.

In the face of growing regulatory trends that tighten restrictions on the use of gamma radiation for food sterilization, and in the face of increasing prohibitions, steam sterilization is becoming the preferred, and in many cases the only viable option.

The PerMix solution is an effective and safe alternative, ensuring a significant reduction in the bacterial population while maintaining the natural quality of the product.

This efficient process typically achieves a full sterilization cycle in as little as 60 minutes per batch, depending on product type and batch size, significantly reducing processing time.

Key Benefits of the PerMix Sterilization System

Gentle and effective sterilization

Our technology uses pressurized steam to quickly eliminate microorganisms, followed by vacuum drying at low temperatures to preserve organoleptic properties of spices.

Functionality

Flexibility

The system is designed for batch operation, allowing you to quickly change between different spice types and ensuring easy and effective cleaning.

Energy efficiency

The unique system design maximizes heat transfer and reduces energy consumption compared to traditional sterilization methods.

Proven bacteria reduction

The system guarantees a TPC level reduction of up to 5 log, meeting the strictest food industry safety standards.

Versatility

Furthermore, since the system is based on a powder mixer, it can also be used for various mixing purposes, such as preparing spice blends or sterilizing existing spice blends (in cases where certain spices in the blend are more sensitive to thermal processes).

Hygienic design

The system meets GMP requirements and has built-in WIP/CIP systems for efficient and automated cleaning.

Maintaining product quality

Thanks to the dynamic mixing process, all spice particles are evenly crushed, which shortens processing time and protects the unique color, aroma and flavor of the spices.

Precise control

The advanced control system allows for precise management of the sterilization process, including control of the final product humidity level.

Modular solution

The system is delivered and designed according to customer needs as a compact and self-contained unit, enabling easy and quick installation even in facilities with limited space.

Description of the sterilization process

The PerMix sterilization process consists of five main steps to ensure efficient and gentle processing of spices:

Stage A

Loading material

Unsterilized spices are loaded into the system.

Stage B

Preheating and drying

Spices are preheated and partially dried to prepare them for the sterilization stage.

Stage C

Steam under pressure

Sterilization

Pressurized steam is injected into the system, ensuring effective elimination of microorganisms.

Stage D

Rapid vacuum cooling and pre-drying

The vacuum helps to quickly cool the spices and initiates the final drying process.

Stage E

Cooling to ambient temperature and unloading

The spices are cooled to room temperature and discharged from the system.

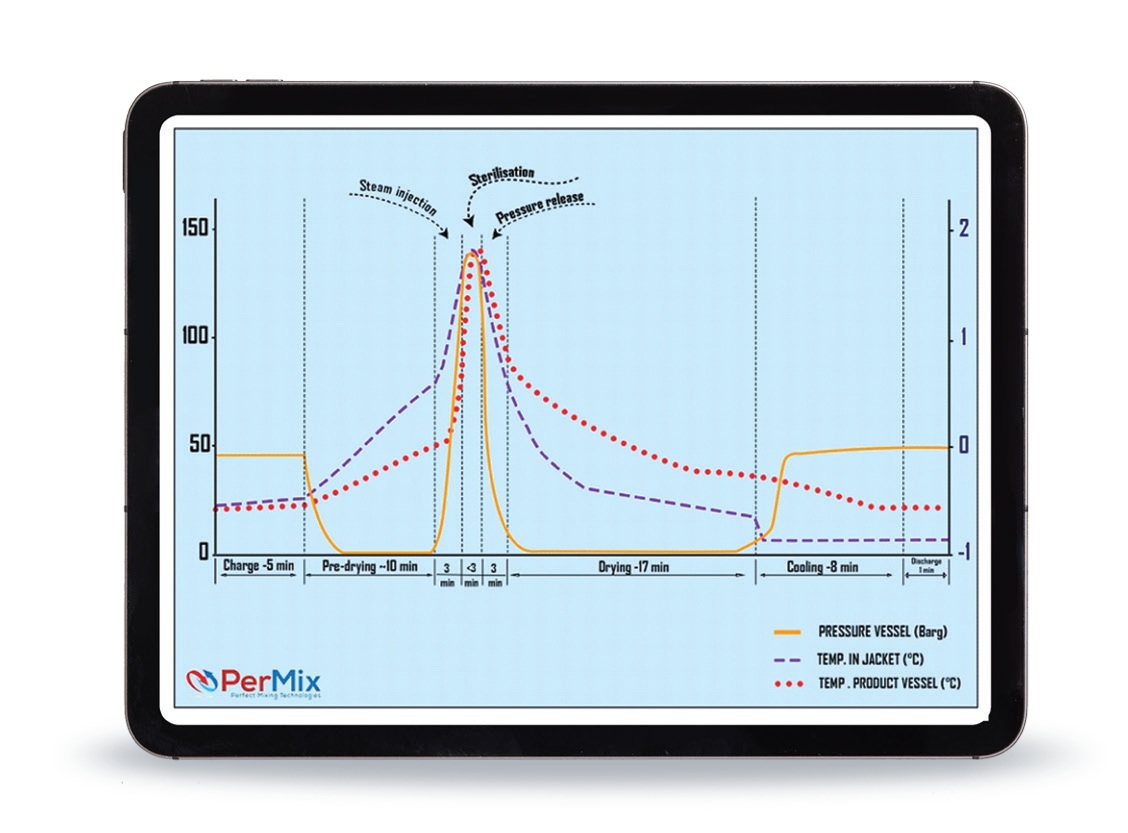

The graph illustrates the changes in temperature and pressure over time during the sterilization process. The X-axis represents time, and the Y-axes represent temperature (dashed red and blue lines) and pressure (yellow line).

Applications

The PerMix dynamic sterilization system is suitable for a wide range of spices, including:

Spice powder

(such as chili, turmeric, curry)

Spice seeds

(such as coriander seeds, cumin seeds, mustard seeds, sesame seeds, allspice seeds, etc.)

Dried herbs

(such as oregano, parsley)

Spice mixtures

Pilot system for spice sterilization

PerMix also offers a small-scale spice sterilization system with a capacity of approximately 15 kg per batch. This system is specifically designed for developing optimal sterilization processes and conducting tests for customers who want to verify the impact of sterilization on their products. It allows for optimization of sterilization parameters before implementing the process on an industrial scale.

PerMix – Your partner in advanced spice sterilization

PerMix is committed to providing its customers with innovative and reliable spice processing solutions. Our dynamic sterilization system allows you to ensure the safety and quality of your products while streamlining production processes and reducing operating costs.