EXAMPLES OF CIP NOZZLE APPLICATIONS:

Standard food grade nozzles

– all our nozzles are manufactured in accordance with the strictest standards and regulations regarding food safety and hygiene.

Standard nozzles with pneumatic cylinder for food applications

For increased safety, the pneumatic actuator is equipped with two position switches as standard (to signal the open/closed position).

Standard nozzles, both liquid powered and air cylinder powered, for food applications

– the nozzle insertion length has been adjusted to pass through the insulating lining placed on the device.

Special nozzles for cleaning waste disposal systems in pharmaceutical applications

– nozzles are manufactured from a special, highly corrosion-resistant alloy with a special surface treatment and a special coating to further increase corrosion resistance in a very aggressive environment.

Custom-made nozzles for cleaning reactors in pharmaceutical applications

– nozzles are manufactured from Hastelloy and are suitable for full vacuum.

The nozzles are completely customized to the needs of the existing reactor, without the need for any modifications to the hardware.

Standard nozzles for pharmaceutical applications

– nozzles are polished to “mirror” quality for increased process safety and are individually marked for improved traceability.

In this case, we were also asked to manufacture some parts of the pipeline to simplify the final assembly.

Specially made nozzles for HCl (hydrochloric acid) scrubber in pharmaceutical applications

– nozzles are manufactured from Hastelloy and are suitable for full vacuum.

The nozzles are completely adapted to the needs of the existing reactor, without the need for any modifications to the equipment. The process connection is also adapted to the customer's requirements.

Standard ATEX nozzles for pharmaceutical applications

– in addition to applying the highest hygiene practices and standards in production, the nozzles are manufactured from materials suitable for use in ATEX classified areas.

Main Features

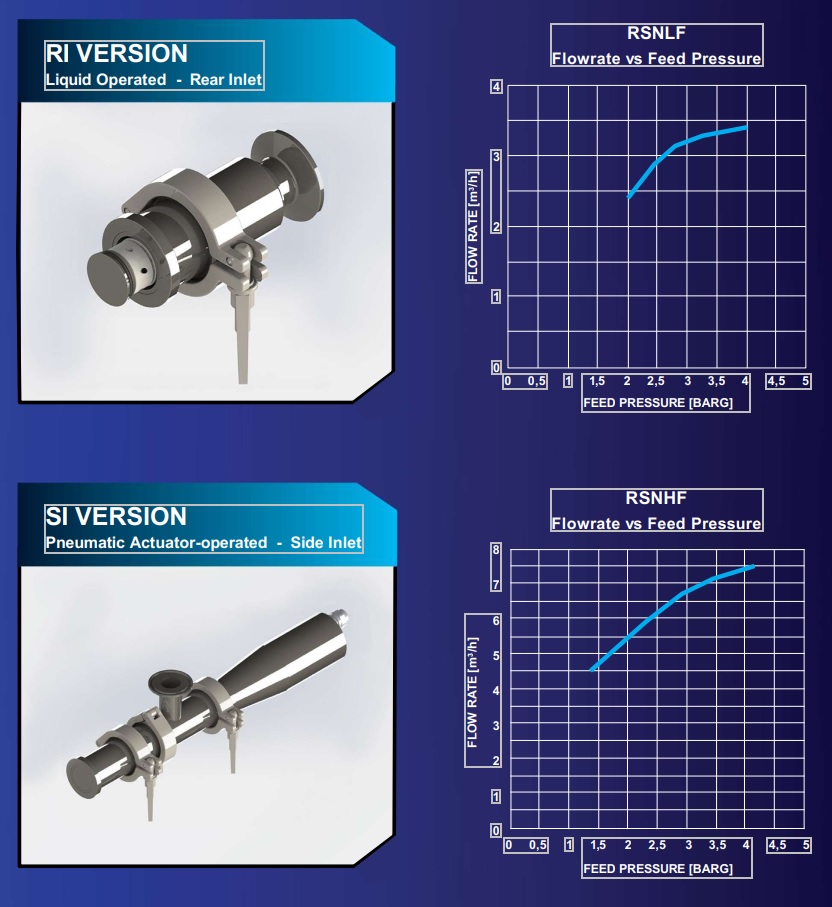

- Standard version powered by liquid, version controlled by pneumatic actuator available on request

- Highly configurable design

- Available in a wide range of dimensions, pitches and materials (stainless steel, hastelloy, etc.)

- Few moving parts, durable construction and easy to use – no maintenance required

- Possibility of mounting directly on the cleaned equipment

- Can be installed through the device insulation or mounted in existing nozzle connections

- Retractable design – no interference with the process

- Special design available for use in full vacuum or ATEX environments