INSTALLATION:

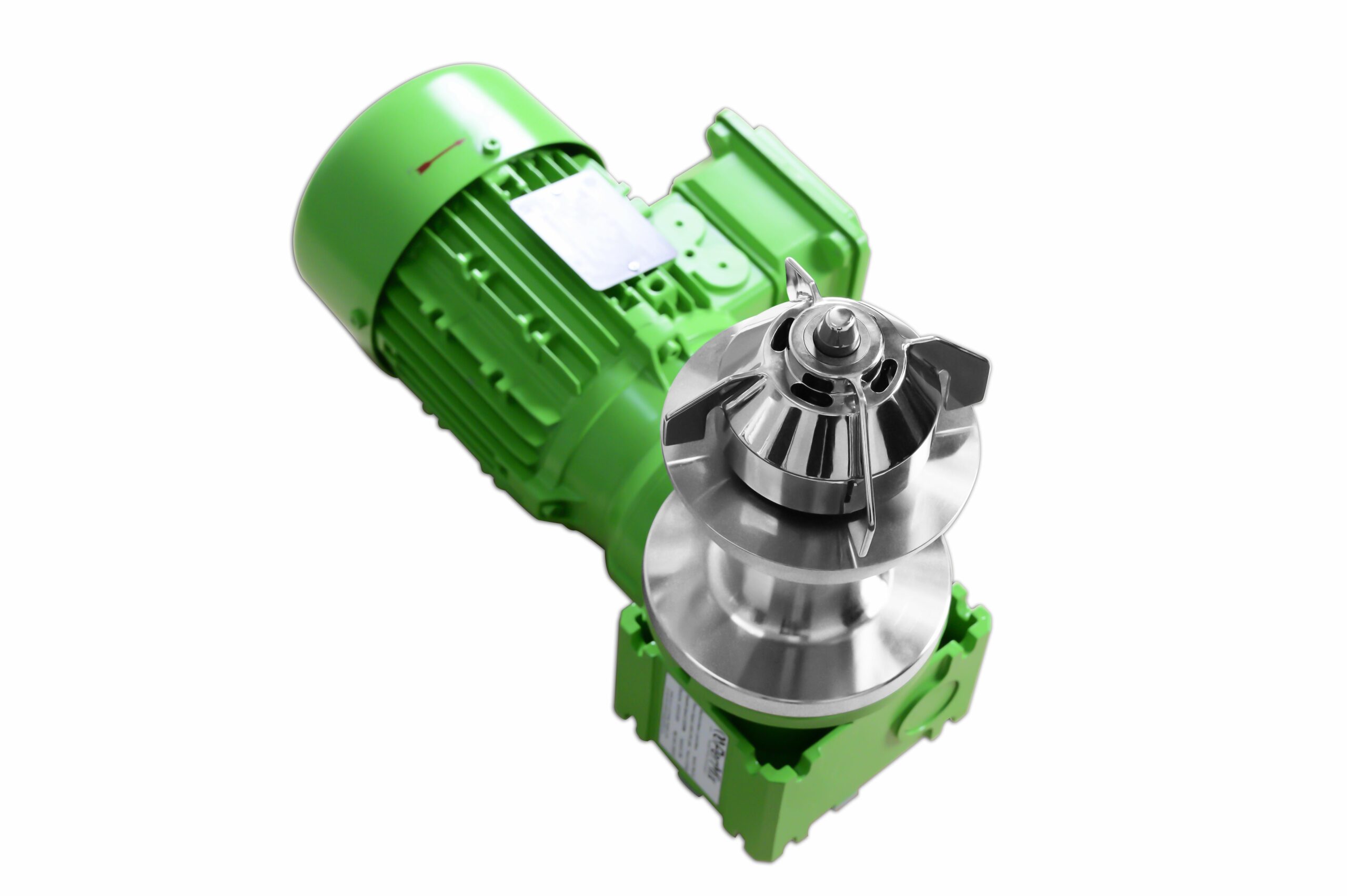

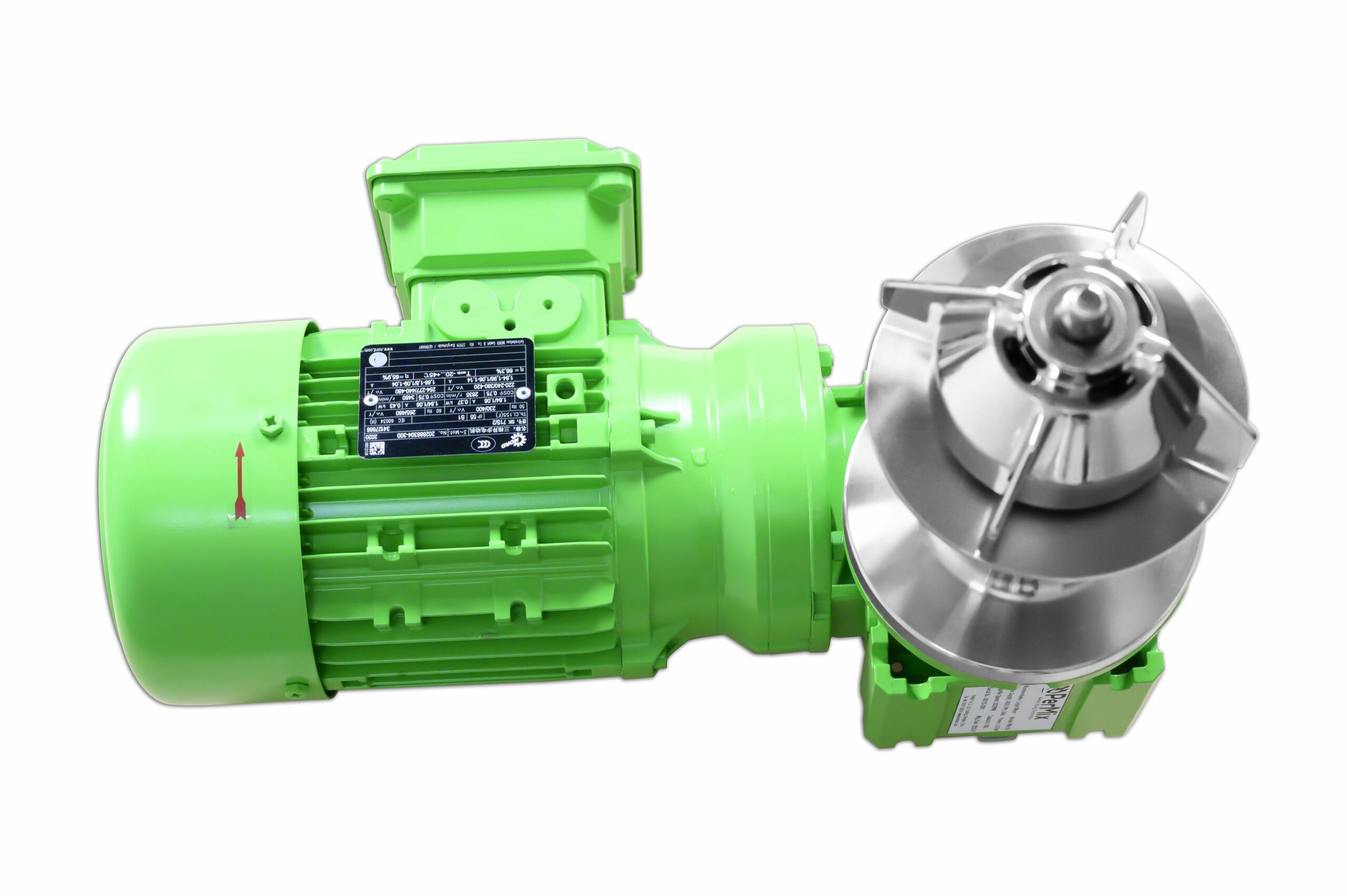

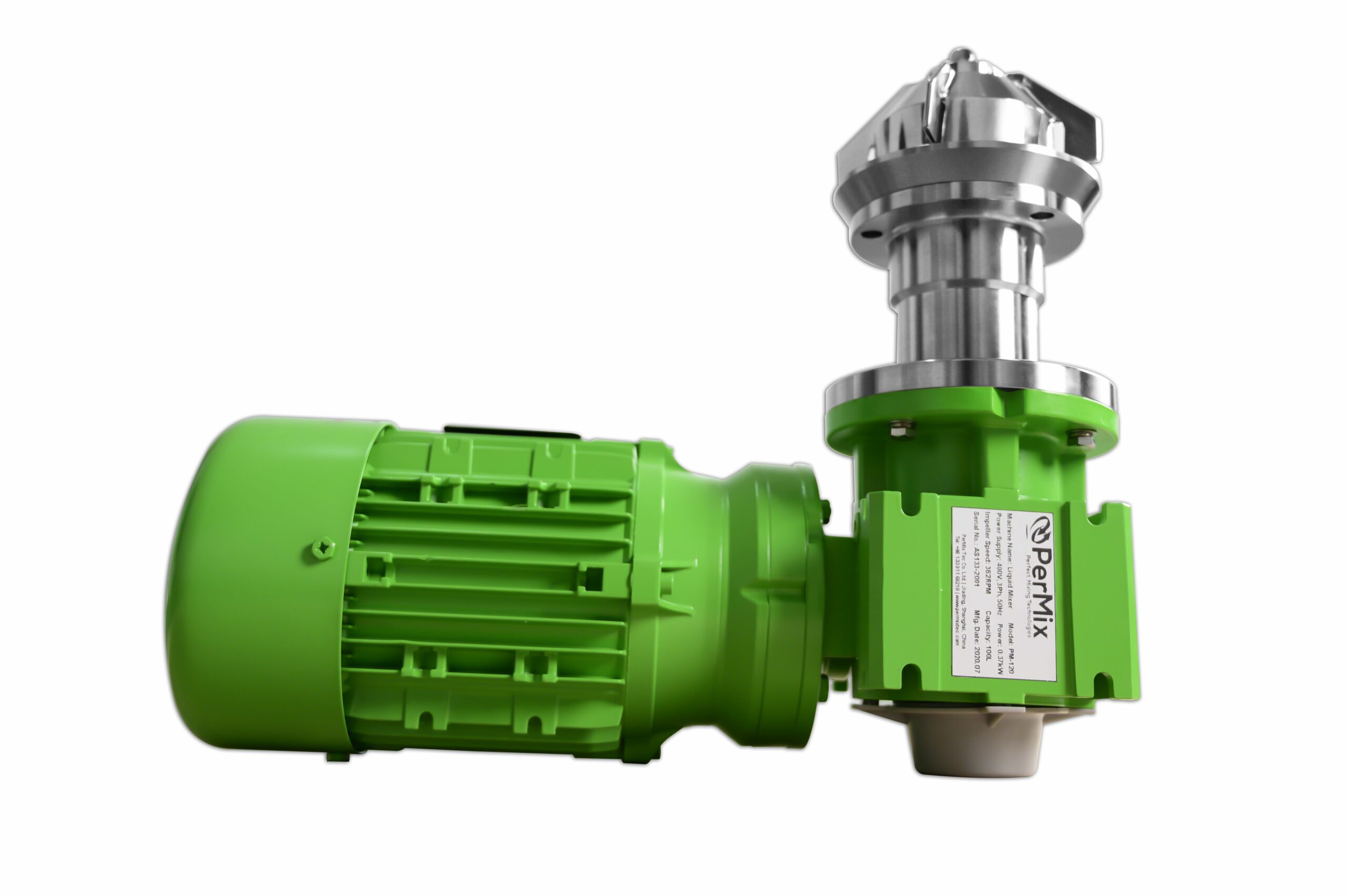

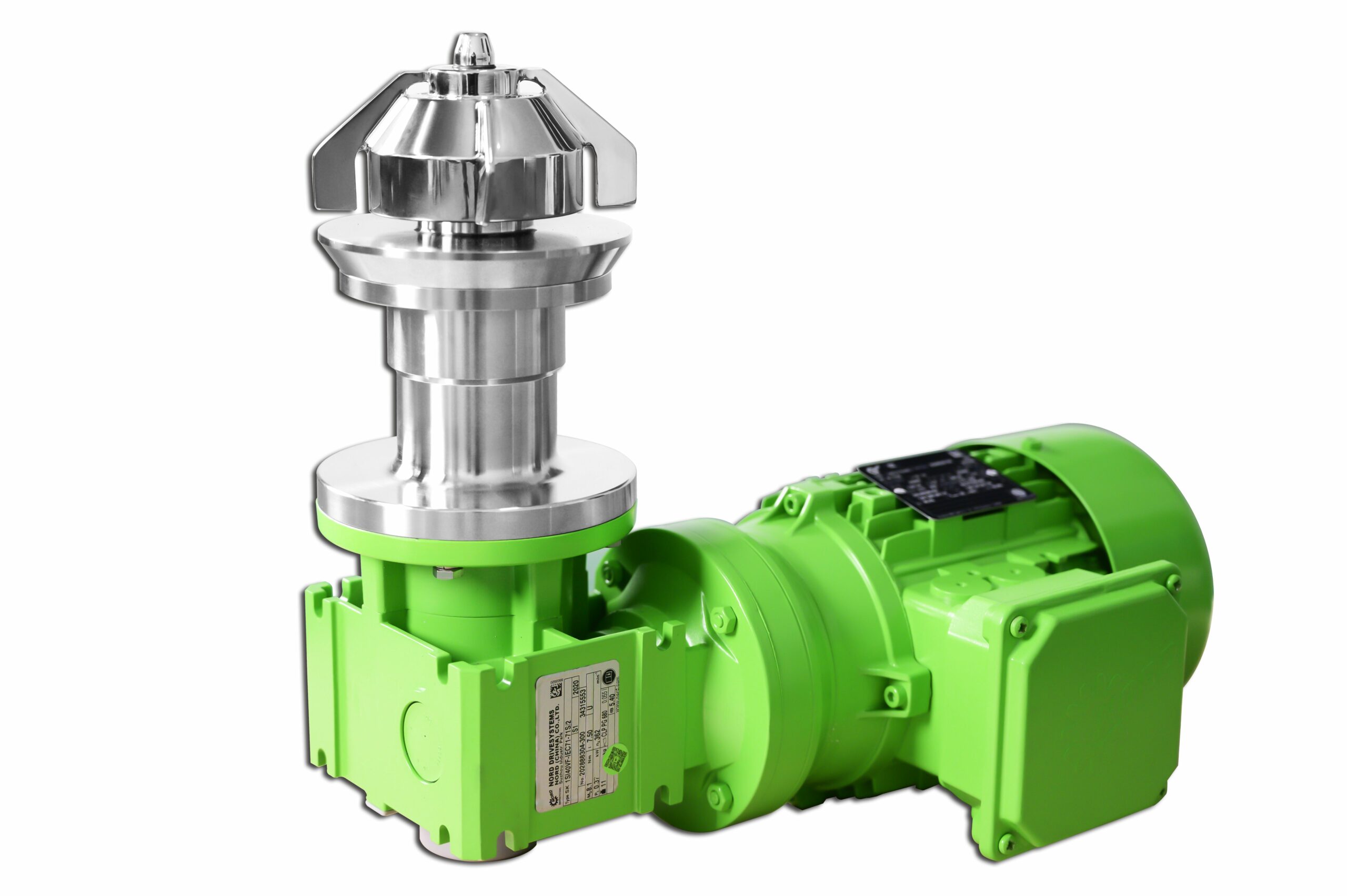

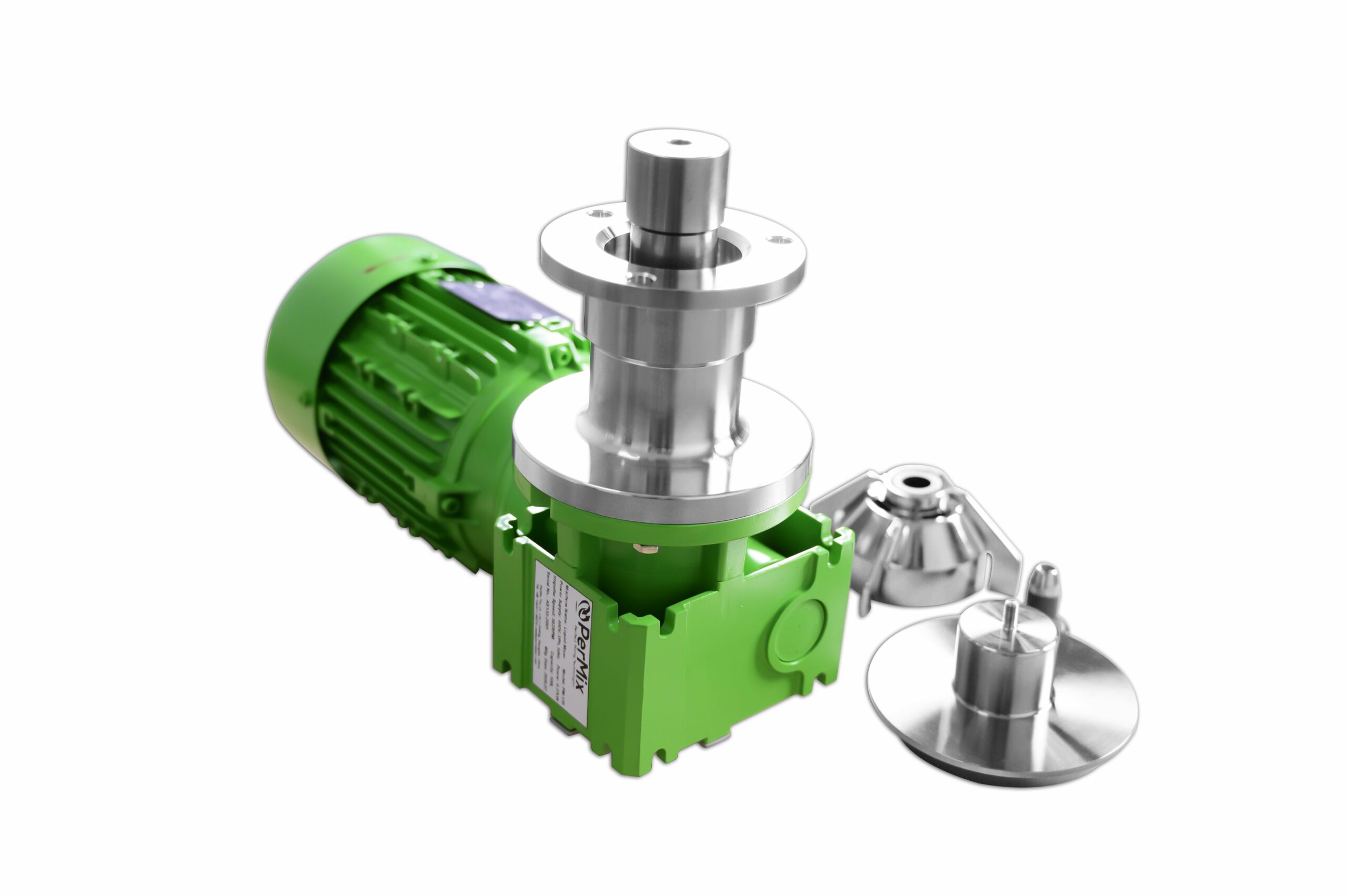

The PM series magnetic mixers are mounted from the bottom of the tank. First, the plate is welded to the bottom of the tank, then the impeller is mounted from the top, while the drive is mounted from the bottom to the plate using screws or latches.

ADVANTAGES AND OPTIONS:

- Low energy consumption with very efficient mixing

- Highly hygienic design, easy to clean and sterilize the tank with steam or hot water

- Bayonet design / Tri-clamp connection for easy drive assembly/disassembly (Optional)

- No sealing and no risk of leakage causing contamination between mixed batches.

- Very low shear forces generated in the mixer for products and materials that are highly sensitive to abrasion

- No wear of mechanical parts, allowing for long use and minimum maintenance

- Explosion-proof construction versions Ex for flammable products (Atex)

- Different types of impellers available for different applications

TECHNICAL CHARACTERISTICS:

| Model | Max. capacity, Liters | Engine power, kW | Impeller diameter | Rotation speed, rpm |

| PM-90 | 50 | 0.12 | 90 | 362 |

| PM-120 | 300 | 0.37 | 120 | 362 |

| PM-155 | 500 | 0.55 | 155 | 362 |

| PM-200 | 1,000 | 0.75 | 200 | 362 |

| PM-220 | 3,000 | 1.5 | 220 | 362 |

| PM-240 | 4,000 | 2.2 | 240 | 362 |

| PM-260 | 6,000 | 3 | 260 | 362 |

| PM-320 | 12,000 | 4 | 320 | 362 |

1) Specific working capacity can be offered as per customer's requirement.

2) The rotation speed can be adjusted according to customer requirements.

3) The technical characteristics are as accurate as possible but are not binding.

3) PerMix reserves the right to modify technical characteristics without prior notice.