PRINCIPLE OF OPERATION:

Working with liquid products often results in the creation and introduction of air or unwanted gases into the products. This causes problems such as oxidation, discoloration, odor, inconsistency or filling difficulties. The PerMix PDA series of vacuum deaerators or degassers are compact and completely sanitary for continuous automatic removal of flavors, air or other gases from any liquid or pasty product using a vacuum.

PerMix PDA V vacuum deaerators can handle a wide range of processes including (but not limited to) food, cosmetics, chemical production that require prevention and protection of applications from air oxidation and ensure their proper preservation. The final products can be e.g. sauces, fruit pulp, cosmetic creams, syrups, PVC dispersions, lubricants, car polishes, shower gels, paraffin and penicillin emulsions, ice creams, adhesive materials, etc.

The PerMix PDA series vacuum deaerators start by generating a very high vacuum in the deaerator chamber down to -0.95 barG, then the product is loaded and the product flows through the deaerator chamber. In most cases the product can be easily sucked into the deaerator chamber by vacuum; for high viscosity products an additional pump may be needed to enable product loading.

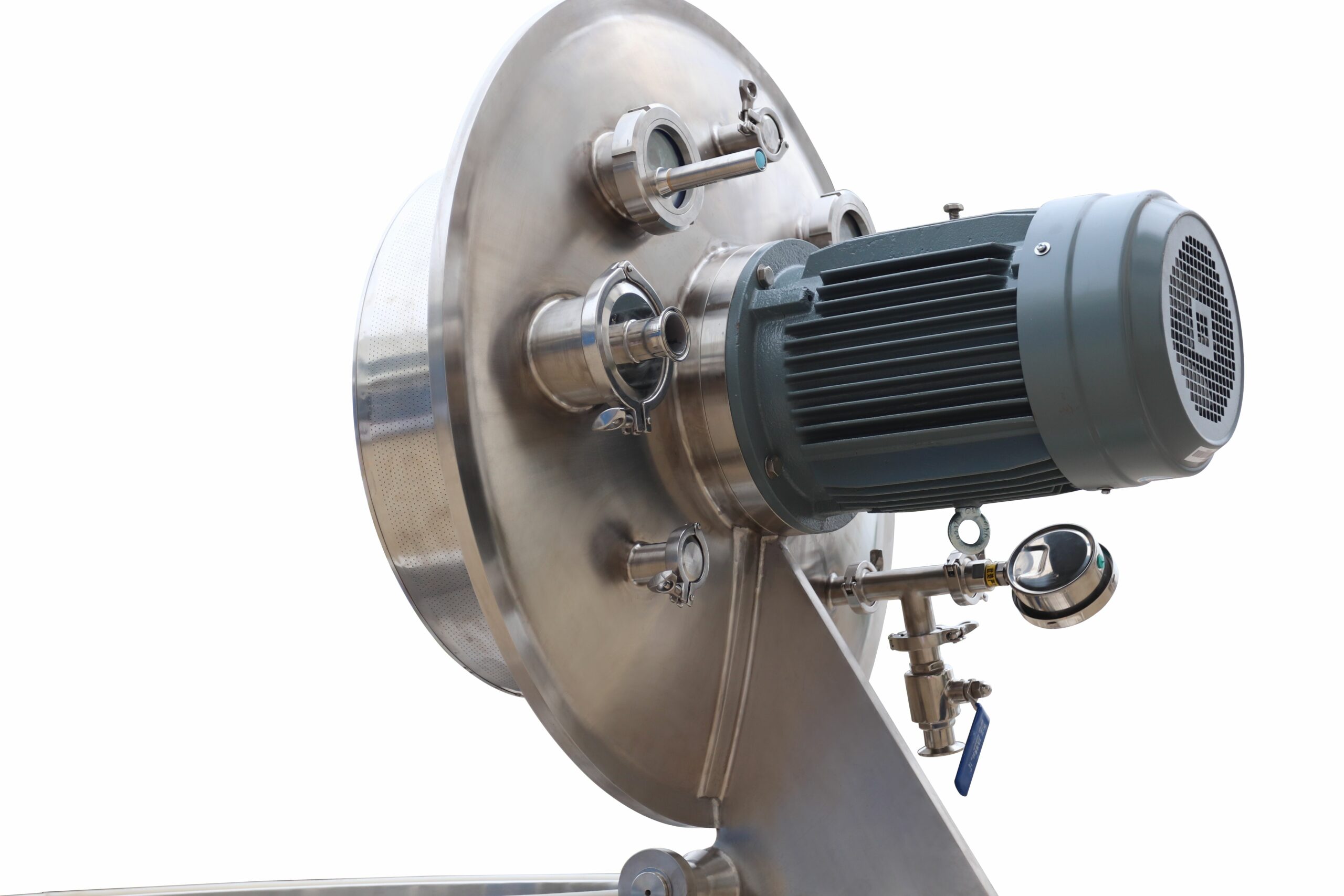

Degassing starts with the formation of a thin layer of product which is first distributed by a high speed centrifugal disc having removable sieves all around it. Depending on the product specification and/or process requirements the number of sieves can be from 0 to 3 and the sieve mesh size can be adjusted. This size can usually be between 1-3 mm.

The creation of a thin layer of product under vacuum conditions in the chamber causes air bubbles in the product to burst and escape, and the product is thus degassed. In addition, during the flow of the product through the sieve mesh, the product particles are subjected to shearing, bending, crushing, etc. forces, which causes even greater separation of air from the product particles.

In the zone behind the rotating disk the product is sprayed at an angle to the chamber walls, then it is retained and flows down by gravity, thus forming another thin layer around the inner surface of the deaerator chamber walls; degassing then continues by means of the vacuum until the product finally reaches the discharge port at the bottom, where it is discharged by means of a positive displacement pump, screw pump, diaphragm pump or other type of pump.

FEATURES AND OPTIONS:

PerMix Vacuum Deaerators can come with many features and options available, including:

- Fully automated unit standing separately with a PLC control cabinet, the so-called Stand Alone Unit

- Explosion-proof design for flammable products (ATEX)

- Pneumatic or electric lifting and lowering of the top cover

- Adjusting the speed of rotation of the centrifugal disc

- Special level gauge for sensitive products

- Various vacuum systems are available

- Various high pressure unloading pumps are available

- Sanitary version

- Heating or cooling jacket

- Special construction materials e.g. acid-resistant steels e.g. Duplex, Titanium, Alloy steels (Hastelloy) etc. etc.

- Mobile construction/machine on wheels

APPLICATIONS:

PerMix PDA series vacuum deaerators can be used in many types of applications, including:

- Food

Baby food, chocolate fillings, chocolate icings, creams, dessert toppings, fruit concentrates. Ketchup, mayonnaise, mustard, salad dressings, sauces, etc.

– Chemicals

Adhesive materials, glues, ink dispersions, detergents, plastics, suspensions, oils, dispersion paints, varnishes.

– Cosmetics and pharmaceuticals

creams, emulsions, gels, balms, ointments, shampoos, toothpaste and other pastes.

TECHNICAL CHARACTERISTICS:

| Model | Working capacity | Flow in l/h | Total power | L | IN | H | H1, with cover open | Libra

| ||

| Light liquid | Sticky products | Very sticky products | ||||||||

| (Liters) | (<300cPs) | (<5,000cPs) | (≥5,000cPs) | (kW) (*) | (mm) | (mm) | (mm) | (mm) | (kg) | |

| PDA-25 | 25 | 1,500 | 900 | 300 | 2.4 | 1,640 | 550 | 1,650 | 1,750 | 470 |

| PDA-65 | 65 | 4,000 | 2,500 | 800 | 4.45 | 1,855 | 715 | 1,780 | 2,200 | 690 |

| PDA-125 | 125 | 8,000 | 5,000 | 1,600 | 7.8 | 2,165 | 850 | 2,170 | 2,500 | 920 |

| PDA-300 | 300 | 15,000 | 9,000 | 3,000 | 14.1 | 2,455 | 1,080 | 2,590 | 3,000 | 1,300 |

| PDA-550 | 550 | 20,000 | 12,500 | 4,000 | 24 | 2,845 | 1,225 | 2,865 | 3,300 | 1,550 |

| PDA-1200 | 1,200 | 30,000 | 18,000 | 6,000 | 32.5 | 3,455 | 1,850 | 3,675 | 4,180 | 2,180 |

1) (*) Including all motors e.g. centrifugal distribution disc, vacuum pump and unloading pump

2) The technical characteristics and illustrations given are as accurate as possible but are not binding.

3) PerMix reserves the right to change the design and technical characteristics without prior notice.