PRINCIPLE OF OPERATION:

Similar to the PS series high shear mixers, there are four steps to explain the operating principle of the PC series inline emulsifiers/homogenizers:

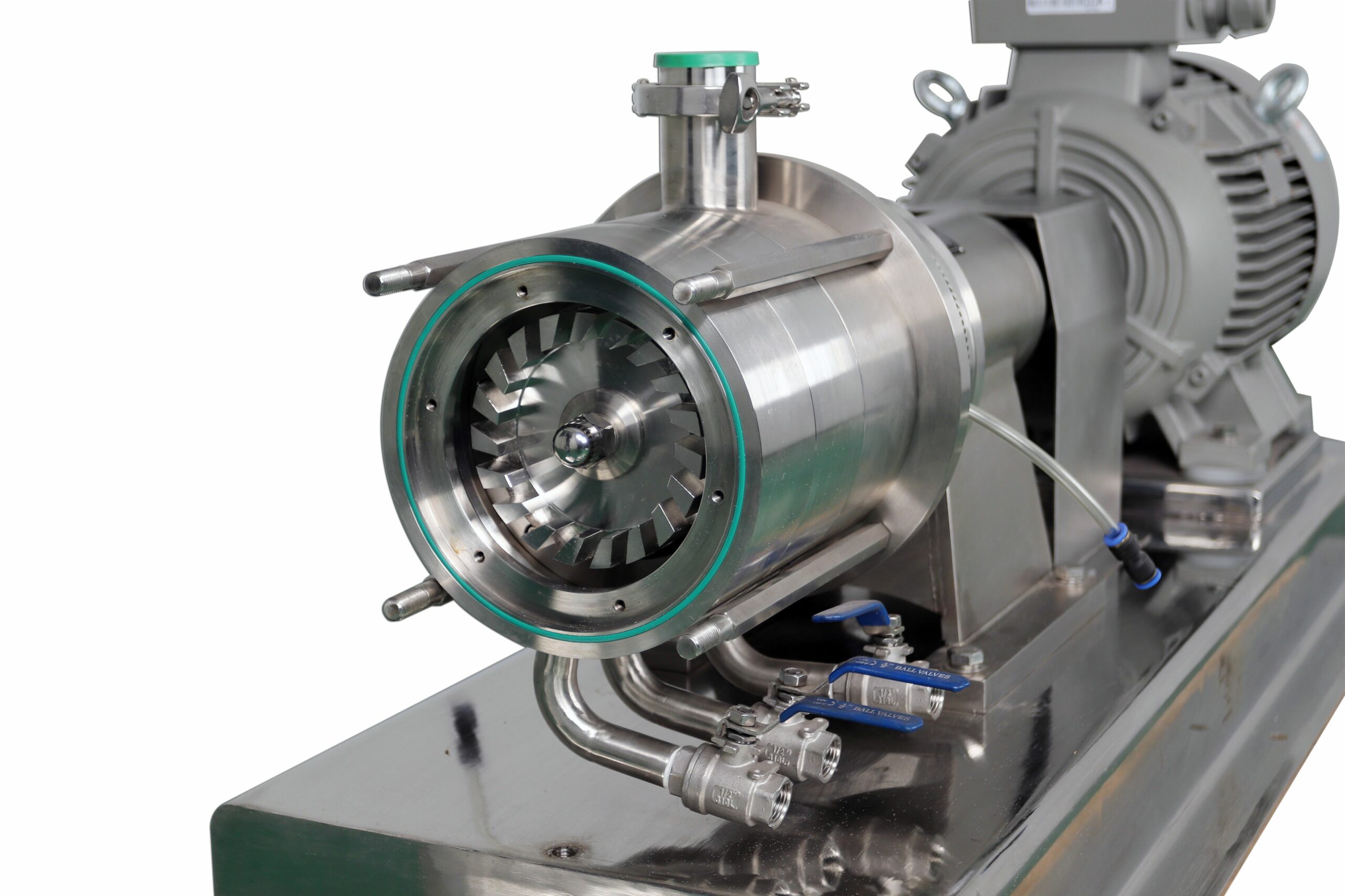

Step 1. When the impeller is driven by the engine, it rotates at a very high speed of several thousand rpm. A strong suction is generated in its center and it draws both solids and liquids from the inlet pipe into the working chamber.

Step 2. The generated centrifugal force throws materials to the periphery of the chamber. Materials are subjected to intensive compression, grinding in a precisely and mechanically made gap between the rotor (impeller) and the stator. High pressure is also created there due to the accumulation of materials, which makes the collisions between particles even greater and gives an even better effect.

Step 3. This is followed by another intense hydraulic fragmentation as the materials are forced through the holes in the stator at very high speeds. As the material particles escape the stator, they tend to explode into thousands of even smaller ones as the pressure drops rapidly.

Step 4. New material is continually drawn into the stator/rotor system, maintaining a circulation or flow through the machine.

STATOR/ROTOR SYSTEM:

PerMix also designs two types of stator/rotor systems: Type K and Type V. Both have several sub-types. These stator/rotor designs offer our customers more options. The customer can select the most appropriate type to handle the specific liquids and solids they are processing.

MULTI-STAGE AND MULTI-ROW STATOR/ROTOR SYSTEM:

- Rows: Each stator and each rotor (impeller) has one or more rows of "teeth" (type K, stator/rotor – impeller) or "vanes" (type V, impeller) or "sieves" (type V, stator).

- Degrees: PerMix provides PC1 series single stage inline emulsifier mixer (homogenizer) and PC3 series multi stage inline emulsifier mixer (homogenizer). PC3 series inline emulsifier mixers (homogenizers) have three stator/rotor sets. The standard PC3 mixer includes coarse, intermediate and fine stator/rotor sets. PC3 series inline emulsifier mixer (homogenizer) is used for difficult to grind materials or when customers require a one-time product flow and there is no possibility of multiple circulations through the machine to achieve the effect.

Multi-stage (usually 3-stage) inline emulsifying mixer (homogenizer) has 3 sets of stator/rotor (impeller) systems to enhance the grinding and comminution effect. This design greatly shortens the processing time, and in some cases, only one pass through the machine can lead to a satisfactory effect.

Depending on the materials being processed and the customer's requirements, each stator/rotor assembly can have just one row or multiple rows of teeth. In addition, PerMix provides different teeth, rough, medium and fine teeth, to achieve different crushing and grinding intensities

SPECIAL DESIGN, ULTRA-HIGH SPEED:

PerMix designs an ultra-high speed linear emulsifying mixer (homogenizer) with a tip speed of about 40 m/s. The ultra-high speed linear emulsifying mixer (homogenizer) is driven by belt transmission to increase the rotor speed to 12,000 rpm (e.g. model: PC-1/60, pilot size).

TERFMOSYPHON WITH DOUBLE MECHANICAL SEALS:

Thermosiphon is used to store and cool buffer liquid for double mechanical seals operating in a closed circuit. It is able to compensate for leakage of buffer liquid in double mechanical seals, so as to avoid their dry operation, which would cause their damage. This ensures increased durability and longer operation of seals.

The buffer liquid flows into the thermosyphon from the double mechanical seals via the thermosyphon effect (or by forced circulation) and returns to the seals replaced and cooled.

The thermosiphon is constructed of 304 or 316L stainless steel, with a pressure gauge, sight glass, all necessary connection nozzles and brackets for easy installation. The tank can be constructed with or without a cooling coil to cool the buffer liquid by the cooling water.

APPLICATIONS:

Inline emulsifying mixers (homogenizers) are widely used by various industries at various stages of processing. They are very efficient to save a lot of energy and time compared to traditional mixing methods.

– Food and beverages

Condensed milk, Salad dressing, Mayonnaise, Ice cream, Cheese, Yogurt, Fruit juices

– Pharmaceuticals and Biotechnology

Drug synthesis, Vaccine, Lipid emulsion, Injectable suspension, Veterinary medicine, Cell extraction

– Cosmetics and daily care products

Detergent, Body gel, Shampoo, Cream, Lotion, Toothpaste, Soap

– Chemical and petroleum industry

Synthetic rubber, resin, bitumen, silicone oil, dye, pigment, coating, ink, nanomaterials

TECHNICAL CHARACTERISTICS:

Single stage, PC-1:

| Model | Watts, kW | RPM @ 50Hz | Maximum efficiency | Diameter in mm [DN] | |

| [L/h] at 1 cPs | Inlet | Departure | |||

| PC-1/60K-Ultra | 4 | 7,500 | 1,500 | 32 | 25 |

| PC-1/80K | 1.5 | 3,000 | 1,500 | 32 | 25 |

| PC-1/100K | 2.2 | 3,000 | 40 | 32 | |

| PC-1/120K | 4 | 4,000 | 40 | 32 | |

| PC-1/140K | 5.5 | 5,000 | 50 | 40 | |

| PC-1/165K | 7.5 | 8,000 | 50 | 40 | |

| PC-1/180K | 11 | 12,000 | 65 | 50 | |

| PC-1/185K | 15 | 18,000 | 65 | 50 | |

| PC-1/200K | 22 | 25,000 | 65 | 50 | |

| PC-1/210K | 37 | 35,000 | 80 | 65 | |

| PC-1/230K | 45 | 50,000 | 100 | 80 | |

| PC-1/245K | 55 | 75,000 | 100 | 80 | |

| PC-1/260K | 75 | 90,000 | 125 | 100 | |

| PC-1/280K | 90 | 110,000 | 125 | 100 | |

| PC-1/290K | 132 | 130,000 | 150 | 125 | |

Three-stage, PC-3:

| Model | Watts, kW | Speed in rpm, at 50Hz | Max. Efficiency | Diameter in mm [DN] | |

| [L/hour] at cPs | Inlet | Departure | |||

| PC-3/80K | 4 | 3,000 | 1,500 | 32 | 25 |

| PC-3/100K | 5.5 | 3,000 | 40 | 32 | |

| PC-3/120K | 7.5 | 4,000 | 40 | 32 | |

| PC-3/140K | 11 | 5,000 | 50 | 40 | |

| PC-3/165K | 18.5 | 8,000 | 50 | 40 | |

| PC-3/180K | 22 | 12,000 | 65 | 50 | |

| PC-3/185K | 30 | 18,000 | 65 | 50 | |

| PC-3/200K | 45 | 25,000 | 65 | 50 | |

| PC-3/210K | 55 | 1,500 | 35,000 | 80 | 65 |

| PC-3/230K | 75 | 45,000 | 100 | 80 | |

| PC-3/245K | 90 | 60,000 | 100 | 80 | |

| PC-3/260K | 110 | 75,000 | 100 | 80 | |

| PC-3/280K | 132 | 95,000 | 125 | 100 | |

- Actual liquid capacity will vary depending on liquid type and different stator/rotor arrangement.

- PerMix offers larger capacity according to customer request.

- PerMix reserves the right to modify the design without prior notice.