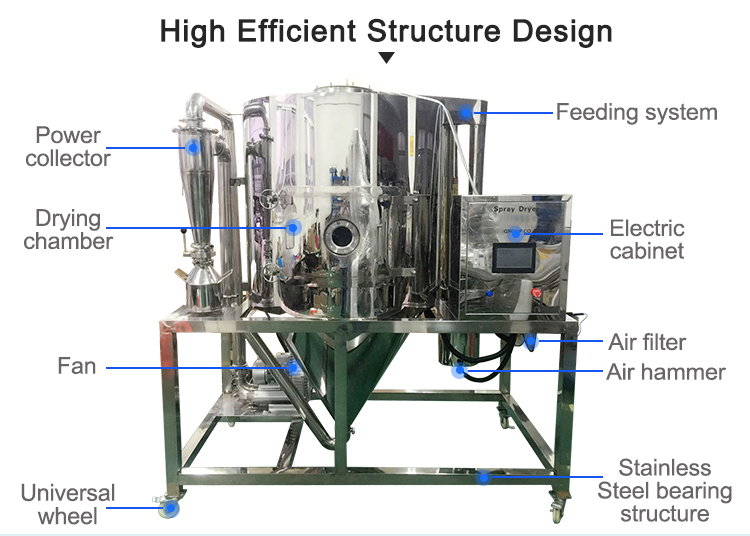

Technical description

Examples of spray dryer applications:

Dairying

– Milk powder SMP, WMP

– Whey, permeate powder,

– WPC, MPC protein powders

– Baby food

– Oiled powders

– Coffee whiteners

Food products

– Egg powders

– Gelatin

– Plant extracts (coffee, herbs)

– Aromas

– Yeast and derivatives

– Soy products

– Fruit extracts

– Vegetable extracts

Pharmaceuticals/Biotechnology

– Enzymes

– Bacteria

– Hormones

– Antibodies

– Antibiotics

– Inhaled pharmaceuticals

Chemicals

– Dyes, pigments

– Polymers

– Resins

– Plant protection products

– Fertilizers

Przykładowa konfiguracja:

| Name | 10L |

| Inlet air temperature control | ≤30-300 °C. |

| Outlet air temperature control | <30 ~ 150 °C. |

| Maximum evaporation of water | 200-10L/h. |

| Centrifugal spray head transmission form | Electric. |

| Speed | 40,000 rpm |

| Spray disc diameter | 80mm |

| Heat source | Electricity |

| Electric heating maximum power | 18kw |

| Total power | 22kw |

| Dimensions L*W*H(mm) | 2500*1600*2800 |

| Dry powder recovery | ≥98% |

| No. | Name | Specification | Material | Quantity |

| 1 | 10L spray dryer | 2500*1600*2800 | Stainless steel | 1 |

| 2 | Tower body | Φ1400*2600 | Stainless steel | 1 |

| 3 | Centrifugal nozzle atomizer | Φ80 10kg per hour | Stainless steel | 1 |

| 4 | Air compressor / vibrating air hammer | Matching | Stainless steel | 2 |

| 5 | Cyclone separator | Φ300 | Stainless steel | 1 |

| 6 | Peristaltic pump | 30-100L/h-0.55kw | Stainless steel | 1 |

| 7 | Induced draft fan | 4kw | Q235A steel | 1 |

| 8 | Electric heaters | 18kw | Stainless steel | 1 |

| 9 | air filter | Matching | Sainless steel | 1 |

| 10 | Electrical control box | PLC | Stainless steel | 1 |

| 11 | Inlet and out wind temperature detector | Matching | Stainless steel | 2 |

| 12 | Air duct | Matching | Stainless steel | 1 |

| 13 | Receiving cylinder | 10L | stainless steel | 1 |

| 14 | Cylinder insulation | 50mm | Insulation cotton | |

| 15 | support | 60*60mm | Stainless steel | 1 |