PRINCIPLE OF OPERATION:

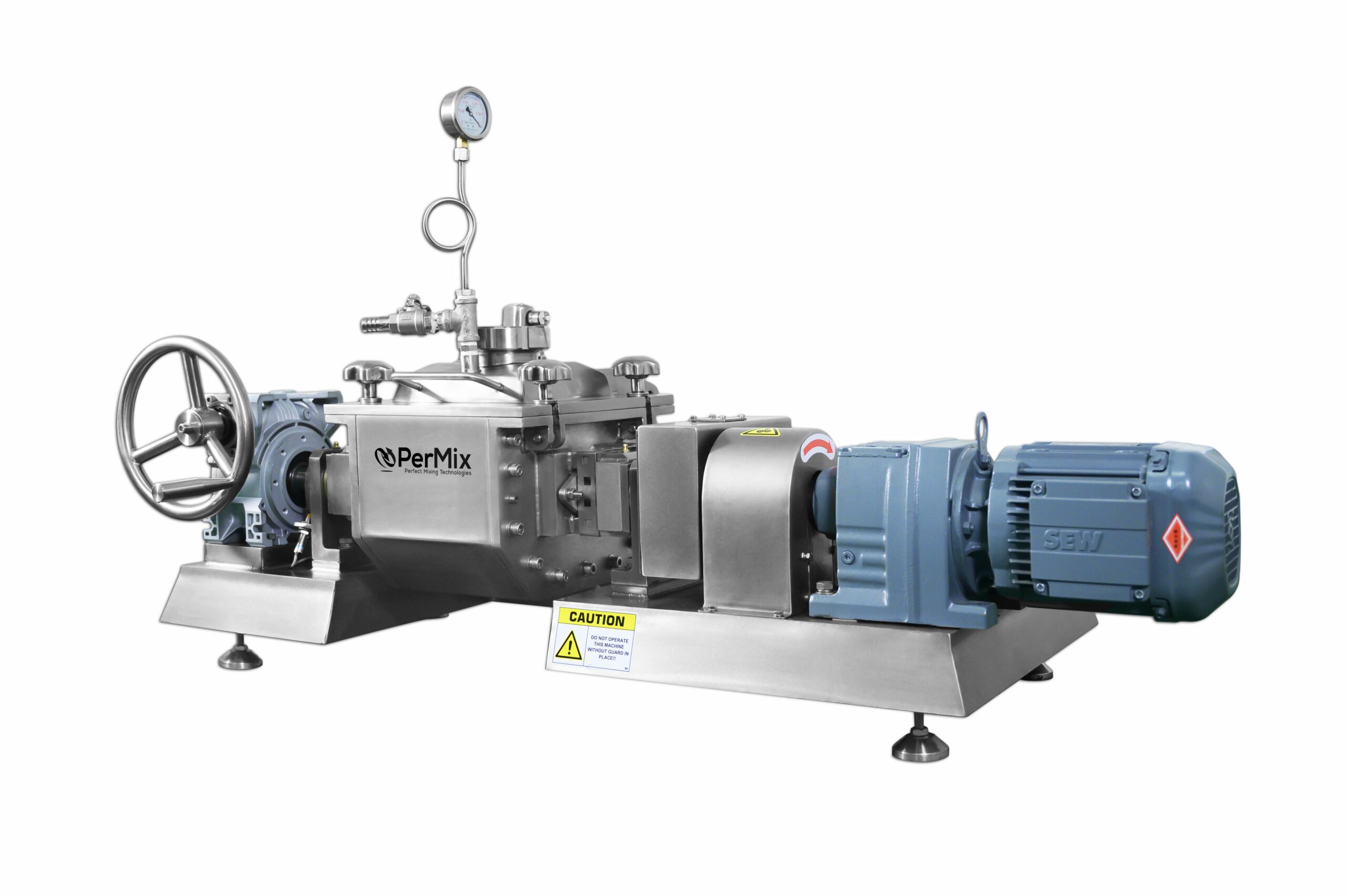

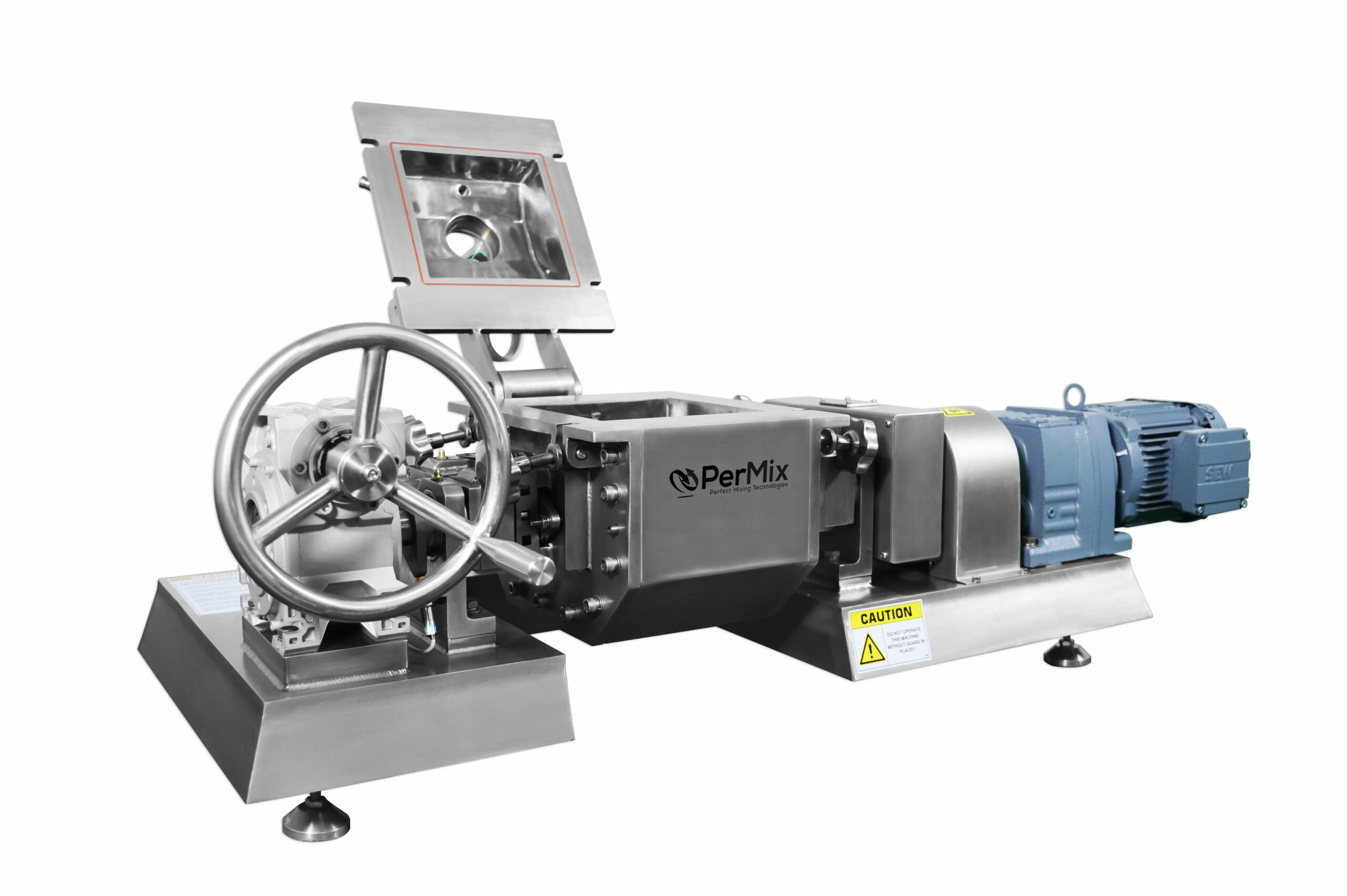

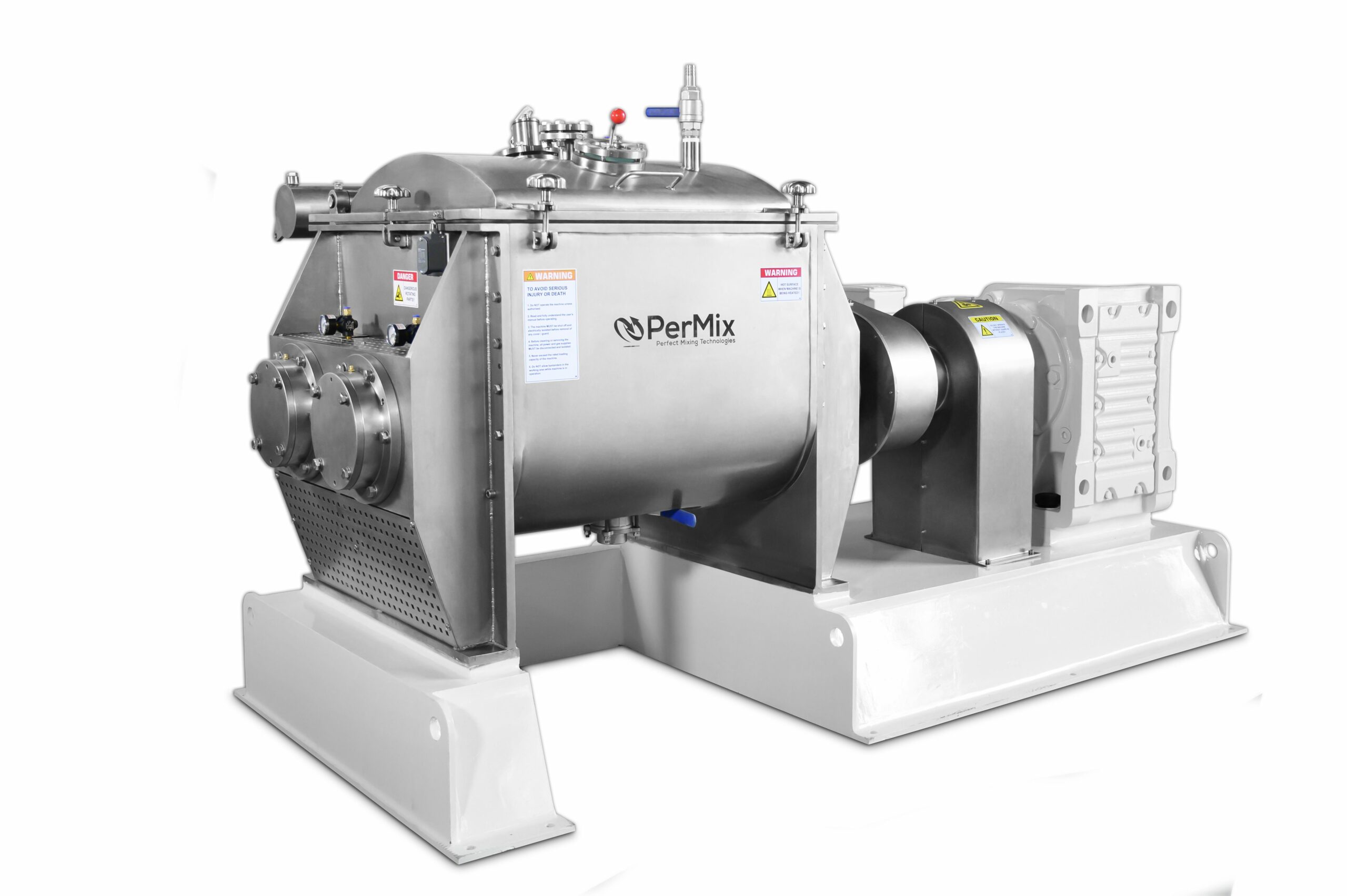

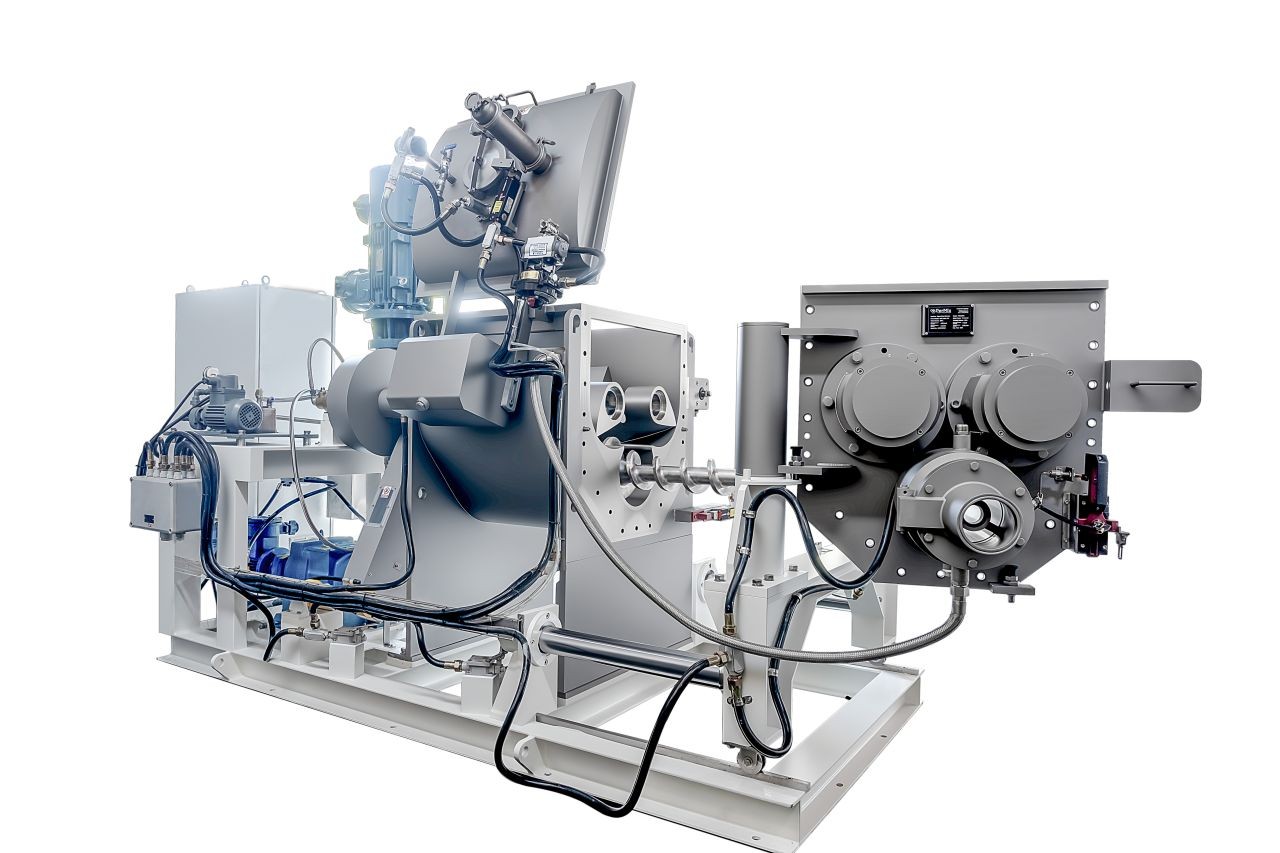

Sigma / zet mixer / PSG mixtruder.

The Sigma PerMix Model PSG mixer has two specially designed Z-shaped rotating elements installed in a W-shaped chamber. The agitators rotate at different speeds (usually at a ratio of 3:2) and in opposite directions.

Mixing is a combination of mass movement, crushing, stretching, bending, dividing and recombining as material is pulled and pressed against blades, bottoms and sidewalls. Constantly new layers of material are compressed and layered on top of each other and subjected to shear forces. New surfaces are created and components can interpenetrate.

The blades, which are ground and polished, successively sweep all points of the trough surface during each revolution, simultaneously dividing the batch continuously and thus quickly influencing a perfectly homogeneous mixture.

UNLOADING SYSTEM:

For PerMix PSG Sigma series mixers, there are mainly three ways to discharge the product after mixing:

(1) Tilting chamber

For small capacity machines (PSG-1 to PSG-15) tilting can be done manually by means of a mechanical mechanism (lever or hand wheel). For larger machines, an electromechanical or hydraulically driven tilting system is provided. PerMix provides a function that causes the blade to rotate at low speed (usually 20% full speed) in the reverse direction in the tilted position to assist unloading by pressing two buttons with both hands.

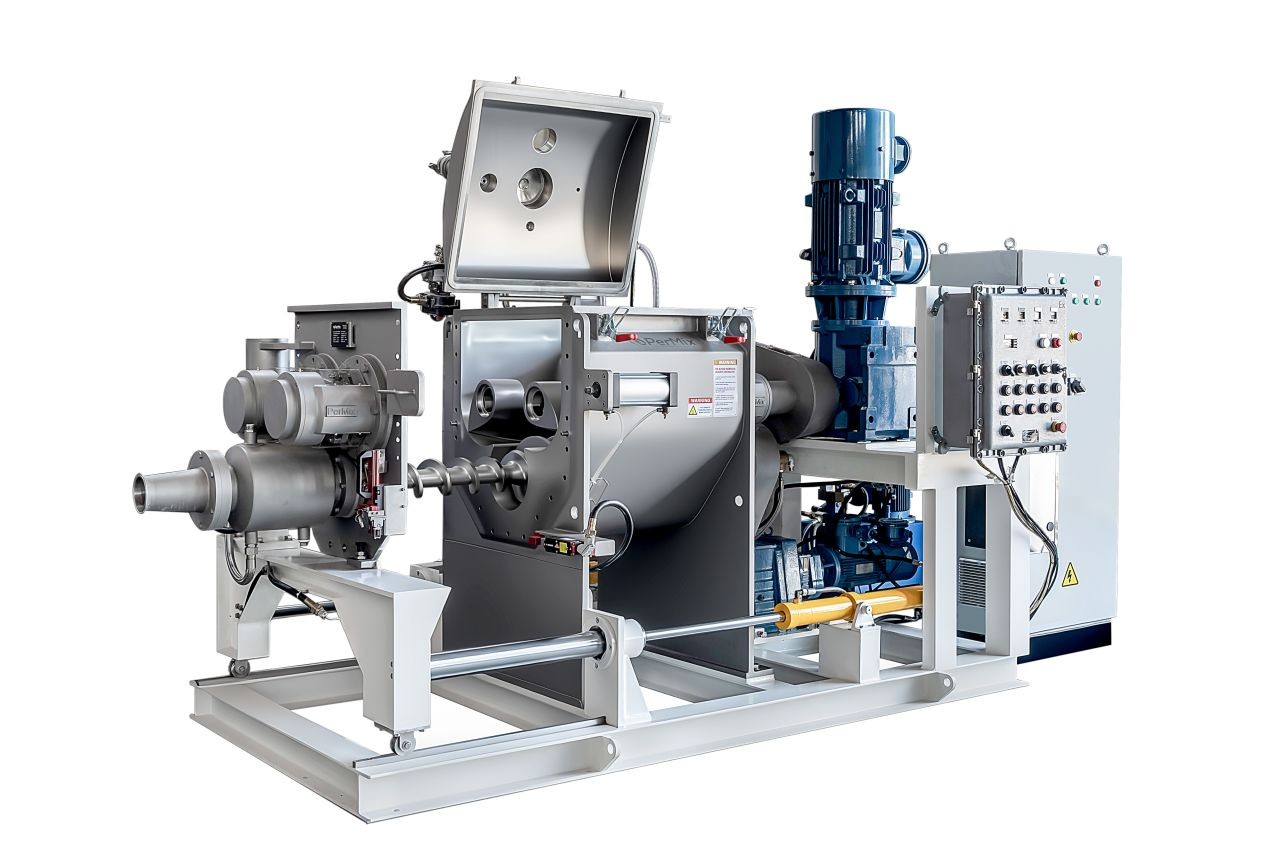

(2) Sembossing screw

The extrusion-discharge screw is located in the lower section and runs in a cylindrical trough tangential to and below the 2 agitators. When the Sigma mixer is equipped with a discharge screw, theInsuch a mixer is called a Sigma Mixer and the model name is PSG-X.

During the mixing cycle, the screw moves the material within the reach of the mixing arms, ensuring that all ingredients are thoroughly mixed while also speeding up the mixing process. During unloading, the direction of the screw rotation is reversed and the mixed material is extruded through the appropriate die holes on the side of the machine. The extruder screw has its own, separate drive, so that the blades and the screw work independently.

PerMix Lab/R&D Sigma mixing extruder with heating and cooling jacket, vacuum and steam injection

(3) Other solutions

Other discharge options are available upon request, such as ball valves or slide valves mounted on the bottom of the trough.

OPTIONS:

A large number of options available for the PerMix PSG Sigma Mixer series allow it to perform specific functions or work as a universal kneader:

– Quick disassembly and easy-to-clean design

– Laboratory size for R&D applications (total capacity 1, 3, 5, 15 l)

-Overlapping arms

– Special “Duplex” kneading arms for intensive kneading

- Variable speed drive

– Hydraulic unit for tilting the chamber

– Designed for operation in vacuum conditions

– Welded jacket for heating and cooling the chamber

– Drilled shaft/arms for heating and cooling

A large number of options are available for the Sigma PerMix PSG mixer series allowing it to perform specific functions or operate as a universal kneader:

– Quick disassembly and easy-to-clean design

– Laboratory size for R&D applications (total capacity 1, 3, 5, 15 l)

-Overlapping arms

– Special “Duplex” kneading arms for intensive kneading

- Variable speed drive

– Hydraulic unit for tilting the chamber

– Designed for operation in vacuum conditions

– Welded jacket for heating and cooling the chamber

– Drilled shaft/arms for heating and cooling

SPECIAL “DUPLEX” KNEADING ARMS.

PerMix offers the Sigma mixer from the PSG-D "Duplex" series, which has been specially developed for even further kneading applications. These are double-chamber kneaders with two levels of kneading knives that are deeply intermeshed and therefore tear. The kneading blades rotate in a 1:2 direction.

Due to the different speeds, the sides of the blades approach and retreat alternately. This causes high tensile and shear coefficients under pressure and therefore high friction in the kneading medium, which ensures excellent dispersion and homogeneity. The shape of the kneading blades allows for an even flow of material from the side walls of the chamber to its center.

Applications in various industries

• Bakery & Confectionery – Discover how Sigma mixers streamline the production of cakes, pastries and confectionery, ensuring consistent quality and reducing processing times.

Solutions-for-the-food-permix industry

• Pharmaceutical Manufacturing – Learn about the pharmaceutical industry's dependence on sigma mixers to precisely blend active pharmaceutical ingredients (APIs), excipients, and other materials to rigorous quality standards.

Solutions-for-the-pharmaceutical-and-nutraceutical-industry

• Plastics & Rubber – Learn how sigma mixers contribute to the efficient mixing of polymers, additives and fillers in the production of high-quality plastics, silicones and rubber compounds.

Solutions for the chemical industry – Fiprocess

SPECIFICATION:

| Model | Total capacity (litres) | Working capacity (litres) | Mixing arm motor power, kW (high viscosity) | Motor power for mixing arms, kW (very high viscosity) | Mixer revolutions, rpm | Length (mm) | Width (mm) | Height (mm) |

| PSG-1 | 1 | 0.6 | 1.1 | 2.2 | 60/47 | 550 | 450 | 700 |

| PSG-3 | 3 | 2 | 1.1 | 2.2 | 65/40 | 650 | 500 | 700 |

| PSG-5 | 5 | 3.5 | 1.1 | 2.2 | 65/40 | 700 | 550 | 730 |

| PSG-10 | 10 | 6 | 1.5 | 3 | 50/35 | 900 | 580 | 691 |

| PSG-15 | 15 | 10 | 2.2 | 5 | 50/28 | 1053 | 623 | 861 |

| PSG-50 | 50 | 30 | 3~5.5 | 5.5~11 | 43/27 | 1330 | 910 | 1350 |

| PSG-100 | 100 | 60 | 5.5~7.5 | 11~15 | 40/25 | 1588 | 984 | 1452 |

| PSG-150 | 150 | 90 | 5.5~11 | 11~15 | 40/25 | 1780 | 990 | 1600 |

| PSG-200 | 200 | 120 | 7.5~15 | 15~22 | 41/26 | 1988 | 1000 | 1829 |

| PSG-300 | 300 | 180 | 7.5~22 | 15~30 | 33/22 | 2730 | 1930 | 1745 |

| PSG-400 | 400 | 240 | 11~30 | 22~37 | 33/22 | 2850 | 1950 | 1800 |

| PSG-600 | 600 | 360 | 30~37 | 55~75 | 35/23 | 3070 | 2080 | 1870 |

| PSG-800 | 800 | 480 | 30~45 | 55~90 | 32/21 | 3270 | 2250 | 1950 |

| PSG-1000 | 1000 | 600 | 37~55 | 75~110 | 32/21 | 4080 | 1560 | 2055 |

| PSG-1500 | 1500 | 900 | 45~75 | 90~160 | 29/19 | 4600 | 1700 | 2330 |

| PSG-2000 | 2000 | 1200 | 55~75 | 110~160 | 29/19 | 5100 | 1850 | 2600 |

1) All specifications are as accurate as reasonably possible but are not binding.

2) The arm speed can be determined by the customer.

3) Custom sizes are available upon request.

4) PerMix reserves the right to modify the design without notice.

TECHNICAL DATA:

| Model | Total capacity (litres) | Working capacity (litres) | Mixing arm motor power, kW (high viscosity) | Motor power for mixing arms, kW (very high viscosity) | Mixer revolutions, rpm | Screw motor power, kW (high viscosity) | Screw motor power, kW (very high viscosity) | Screw speed, rpm |

| PSG-1X | 1 | 0.6 | 1.1 | 2.2 | 60/47 | 0.55 | 1.1 | 59 |

| PSG-3X | 3 | 2 | 1.1 | 2.2 | 60/47 | 0.55 | 1.1 | 59 |

| PSG-5X | 5 | 3.5 | 1.1 | 2.2 | 60/47 | 0.55 | 1.1 | 59 |

| PSG-10X | 10 | 6 | 1.5 | 3 | 53/38 | 0.75 | 1.5 | 60 |

| PSG-15X | 15 | 10 | 2.2 | 5 | 50/28 | 1.1 | 2.2 | 60 |

| PSG-50X | 50 | 30 | 3~5.5 | 5.5~11 | 43/27 | 1.5 | 3 | 58 |

| PSG-100X | 100 | 60 | 5.5~7.5 | 11~15 | 40/25 | 3 | 4 | 58 |

| PSG-150X | 150 | 90 | 5.5~11 | 11~15 | 40/25 | 3 | 5.5 | 57 |

| PSG-200X | 200 | 120 | 7.5~15 | 15~22 | 41/26 | 3 | 5.5 | 51 |

| PSG-300X | 300 | 180 | 7.5~22 | 15~30 | 33/22 | 4 | 7.5 | 51 |

| PSG-400X | 400 | 240 | 11~30 | 22~37 | 33/22 | 5.5 | 11 | 51 |

| PSG-600X | 600 | 360 | 30~37 | 55~75 | 35/23 | 11 | 30 | 53 |

| PSG-800X | 800 | 480 | 30~45 | 55~90 | 32/21 | 11 | 30 | 53 |

| PSG-1000X | 1000 | 600 | 37~55 | 75~110 | 32/21 | 15 | 37 | 50 |

| PSG-1500X | 1500 | 900 | 45~75 | 90~160 | 29/19 | 18.5 | 45 | 45 |

| PSG-2000X | 2000 | 1200 | 55~75 | 110~160 | 29/19 | 22 | 55 | 45 |

1) All specifications are as accurate as reasonably possible but are not binding.

2) The arm speed can be determined by the customer.

3) Custom sizes are available upon request.

4) PerMix reserves the right to modify the design without notice.