PRINCIPLE OF OPERATION:

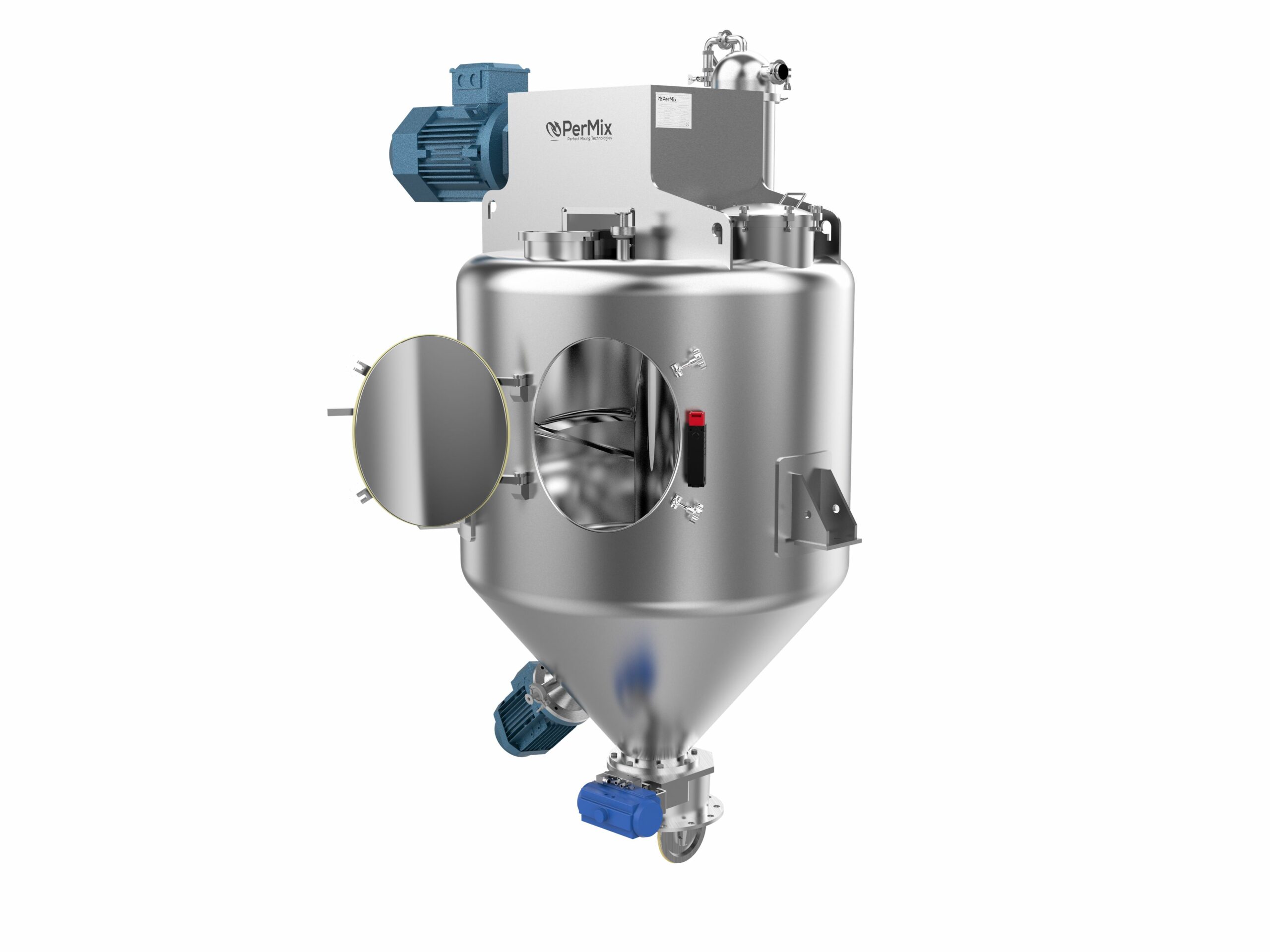

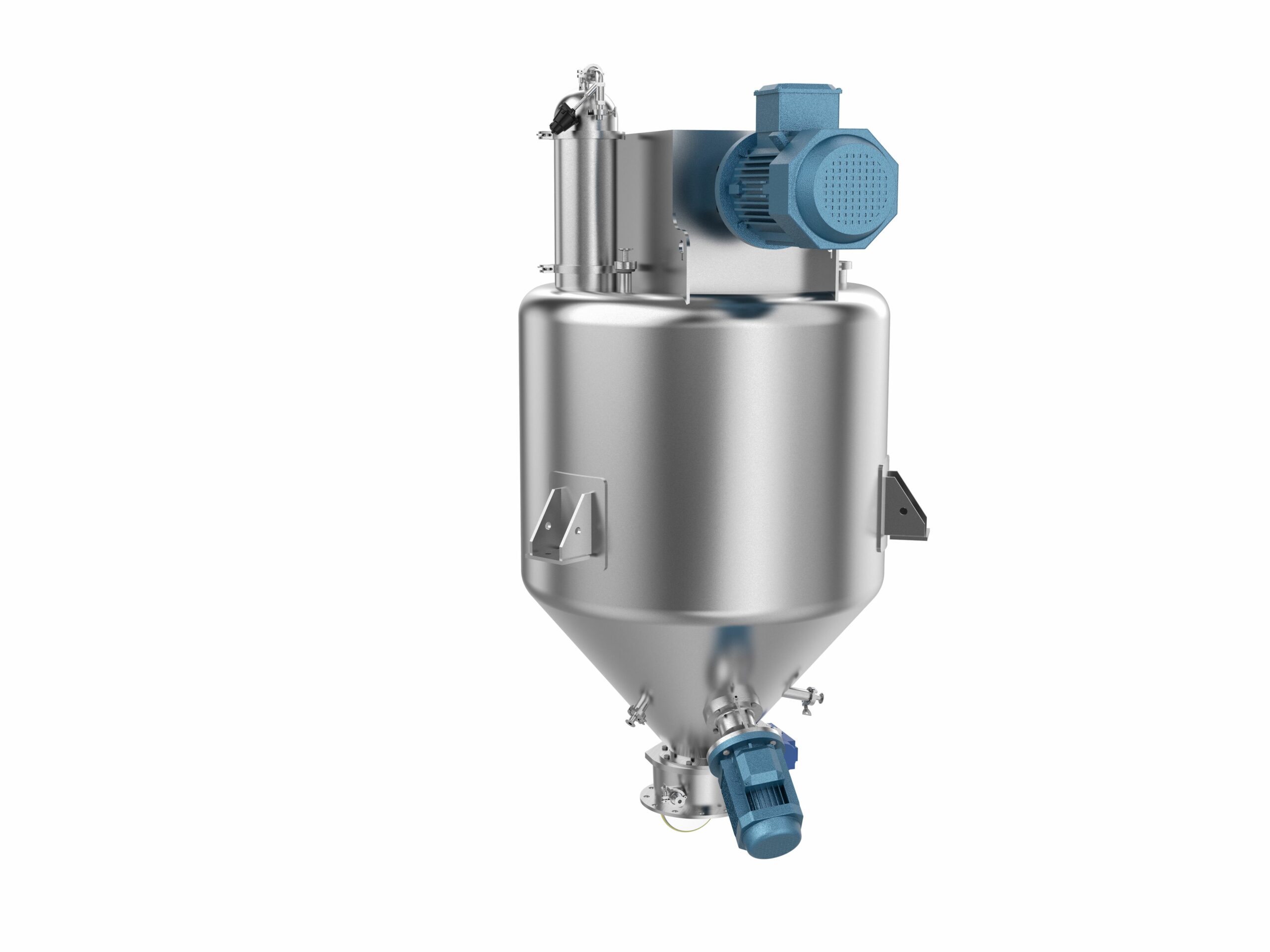

PerMix Vertical Paddle Mixers are designed with a single shaft with only one ribbon, but are capable of providing multi-dimensional movement of materials. They have a cylindrical body with a conical bottom, but can sometimes be made with a flat bottom and scrapers

There is a flush access door on the side for inspection and cleaning. A flush plug valve is mounted on the bottom for product discharge.

The ribbon inside the mixing chamber moves the materials upwards from the bottom to the top, where the materials then fall by gravity into the center. This generates a good counterflow of the product particles. The ribbon mixer design ensures that the linear velocity of the particles is different at different locations, resulting in a turbulent flow field. During this continuous operation, there is a rapid exchange of material particles and heat, which leads to a homogeneous product.

In addition, the material particles are mixed with minimal mechanical and thermal stress, which makes this type of mixer a good solution for delicate and heat-sensitive products.

ADVANTAGES

- High mixing accuracy 1:1,000,000

- Gentle mixing action for sensitive materials without generating heat

- Possibility of installing a crusher (chopper) to intensify mixing and crushing lumps

- Requirements: low minimum input quantity

- Complete unloading with minimal residue

- Easy to clean, dry or wet

- High heat transfer efficiency, ideal for heating or cooling powders

OPTIONS:

Construction material and surface treatment

Our mixers can be made of carbon steel, stainless steel AISI 304, AISI 316, AISI 316L, titanium, Hastelloy, etc. Stainless steel can be polished to “mirror quality” or sandblasted.

Product feeding and unloading

Customers can choose from a variety of product feeding and unloading methods.

Heating/cooling jacket

Jacket over chamber for heating or cooling.

Vacuum drying and deaeration

The PAM mixer can be designed for vacuum drying and deaeration or other pressure operation for special applications.

Spray nozzle

It is possible to add liquid to the powder using the spray nozzle mounted on the top.

TECHNICAL CHARACTERISTICS:

| Model | Total capacity (Liters) | Working capacity (Liters) | Power (*) (kW) | Shaft revolutions (rpm) |

| PAM-150 | 150 | 105 | 1.1 ~ 5 | 105 |

| PAM-300 | 300 | 210 | 3 ~ 8 | 83 |

| PAM-400 | 400 | 280 | 5 ~ 15 | 73 |

| PAM-500 | 500 | 350 | 7 ~ 21 | 66 |

| PAM-750 | 750 | 525 | 8 ~ 27 | 61 |

| PAM-1000 | 1000 | 700 | 12 ~ 40 | 52 |

| PAM-1500 | 1500 | 1050 | 14 ~ 48 | 48 |

| PAM-2000 | 2000 | 1400 | 19 ~ 64 | 42 |

| PAM-3000 | 3000 | 2100 | 22 ~ 78 | 38 |

| PAM-4000 | 4000 | 2800 | 29 ~ 101 | 33 |

| PAM-5000 | 5000 | 3500 | 34 ~ 120 | 30 |

| PAM-6000 | 6000 | 4200 | 34 ~ 120 | 30 |

| PAM-7000 | 7000 | 4900 | 38 ~ 137 | 28 |

| PAM-8000 | 8000 | 5600 | 43 ~ 153 | 26 |

| PAM-10000 | 10000 | 7000 | 47 ~ 167 | 25 |

| PAM-12000 | 12000 | 8400 | 50 ~ 180 | 24 |

| PAM-15000 | 15000 | 10500 | 57 ~ 205 | 22 |

| PAM-20000 | 20000 | 14000 | 63 ~ 227 | 21 |

-All specifications and illustrations are as accurate as possible but are not binding.

– PerMix reserves the right to modify the design without notice.

SEE ALSO:

Solutions-for-the-food-permix industry

Solutions-for-the-pharmaceutical-and-nutraceutical-industry

Solutions for the chemical industry – Fiprocess