Types of PerMix induction mixers:

PerMix offers (4) types of powder liquid mixers that cover the typical market product range:

(1) PT-C/Q (double wall construction)

(2) PT-C/Y (special stator/rotor system)

(3) PT-C/F (two-pump design)

(4) PCH (grinding pump/homogenizer)

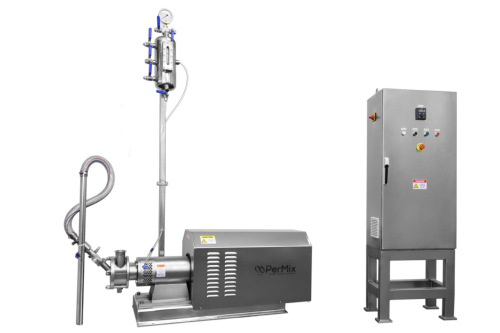

With many outstanding features and options, PerMix PT-C series powder liquid mixers are widely used for mixing almost all types of powder products in various industries, e.g. food and beverage, dairy care, pharmaceutical, chemical.

Principle of operation:

The four types of powder liquid mixers have a similar operating principle but with some difference:

(1) PT-C/Q (double wall construction)

The PerMix PT-C/Q series powder liquid mixer is the most popular type, also called Tri-blender. It consists of two key parts: casing pipe and stator/rotor system.

The casing pipe is built vertically and coaxially into the inlet of the stator rotor system. This double design prevents powder from contacting the liquid through the casing pipe and forming lumps before both reach the stator/rotor system.

Since the rotor operates at high speed during operation, the liquid enters the chamber and a water ring is formed. A vacuum is created inside, which causes the powder to be sucked from the reservoir above the chamber.

A valve at the bottom of the hopper is used to regulate the rate of powder fall. As soon as the powder comes into contact with the liquid, it is wetted and dispersed in the liquid by turbulence and later by high shear force as the mixture passes through the precisely machined mechanical gap between the stator and the rotor (rotor) passes through the stator holes.

By selecting different types of stator rotor systems, different functions of powder wetting, homogenization, etc. can be provided. PerMix provides high shear stator rotor system and low shear stator rotor system. In some cases, when the powder is easily dissolved in the liquid, only the ordinary centrifugal pump rotor without stator is used, which provides higher volume flow and higher powder feed rate.

(2) PT-C/Y (Special stator rotor system)

The PerMix PT-C/Y series powder liquid mixer has a particularly specially designed stator/ rotor (impeller) that operates on the water ring pump principle, which is able to generate a relatively high vacuum; this vacuum makes the PT-C/Y mixer able to suck powder from a hand-held tube or from another container at ground level. Powder can also be fed by gravity from a vertical hopper with a much higher powder suction rate.

(3) PT-C/F (two-pump design)

PT-C/F series powder liquid mixing system is designed with the combination of self-priming pump and in-line homogenizing mixer. The self-priming pump takes the liquid from the external container, and when the liquid passes through the venturi tube which is located at the bottom of the powder hopper, a vacuum is generated there and sucks the powder from the feeder. The powder and liquid mixture will first pass through the self-priming pump, and then be sheared and dispersed in the in-line homogenizing mixer.

(4) PCH (pulper pump)

By adding a hopper at the liquid inlet, our PCH series shear pump can be converted into a powder-liquid mixer to provide perfectly good suction performance for dry and free-flowing powders, for example, milk powder, dry flour, etc. Due to its relatively simple and compact design and full stainless steel construction, the PCH series models are widely used in many hygienic applications.

Usage:

Some typical uses include:

- Preparation of syrup, sorbitol, glucose, lactose, etc.

- Reconstitution of milk powder, whey, protein, etc.

- Dissolving CMC, Xanthan Gum, etc.

- Preparation of flour and starch suspensions

- Preparation of brines

- Premixes of yogurt and other milk-based desserts

- Bentonite suspension, TiO2 in pigments, premixes for yogurt and other milk-based desserts

- Preparation of pesticides and fertilizers

Options:

There are many options available for the PT-C Series Powder Liquid Mixers:

- powder hose assembly held by hand

- multi-speed motor, inverter

- multi-row and multi-stage stator rotor system

- metal parts made of AISI 316L acid-resistant steel or other

- sealing made of FPM, FFPM, etc.

- feeder with angle 50°, 60°, etc.

- vibrating or air brush feeder

- single or double mechanical seal

Technical characteristics:

(1.1) PT-C/Q-HS (Double Wall Construction/High Abrasion Stator/Rotor System)

| Model | Watts, kW | RPM @ 50Hz | Max. liquid flow capacity, Ton/hour | Max. powder output, Kg/min |

| PT-C/Q-80HS | 1.5 | 3,000 | 1.5 | 5 |

| PT-C/Q-100HS | 2.2 | 3 | 10 | |

| PT-C/Q-120HS | 4 | 4 | 15 | |

| PT-C/Q-140HS | 5.5 | 5 | 20 | |

| PT-C/Q-165HS | 7.5 | 8 | 30 | |

| PT-C/Q-180HS | 11 | 12 | 50 | |

| PT-C/Q-185HS | 15 | 18 | 80 | |

| PT-C/Q-200HS | 22 | 25 | 120 | |

| PT-C/Q-210HS | 37 | 35 | 180 | |

| PT-C/Q-230HS | 45 | 40 | 220 | |

| PT-C/Q-245HS | 55 | 50 | 250 | |

| PT-C/Q-260HS | 75 | 75 | 300 | |

| PT-C/Q-280HS | 90 | 90 | 400 | |

| PT-C/Q-290HS | 132 | 110 | 500 |

1) Actual liquid and powder output will vary depending on material characteristics and type of stator rotor system.

2) The machine is equipped with one stator rotor system.

3) PerMix offers special models according to customer requests.

4) PerMix reserves the right to modify the design without prior notice.

(1.2) PT-C/Q-LS (double wall design), with a light grinding Stator/Rotor system

| Model | Watts, kW | RPM, 50Hz | Max. Liquid capacity, Ton/hr | Powder output, Kg/min |

| PT-C/Q-LS1 | 3 | 3,000 | 15 | 5~20 |

| PT-C/Q-LS2 | 11 | 3,000 | 25 | 15~50 |

| PT-C/Q-LS3 | 22 | 1,500 | 40 | 30~120 |

1) Actual liquid and powder yield will vary depending on material characteristics.

2) PerMix offers special models according to customer requests.

3) PerMix reserves the right to modify the design without prior notice.

(2) PT-C/Y (Special Stator Rotor System)

| Model | Watts, kW | RPM, 50Hz | Max. liquid capacity, Ton/hr | Powder capacity, Kg/min (manually operated) |

| PT-C/Y-120 | 7.5~11 | 3,000 | 10 | 1~3 |

| PT-C/Y-140 | 15~30 | 20 | 2~5 | |

| PT-C/Y-165 | 37~45 | 40 | 3~12 | |

| PT-C/Y-180 | 55~75 | 1,500 | 60 | 5~25 |

| PT-C/Y-220 | 110~160 | 100 | 8~50 |

1) Actual liquid and powder capacity will vary depending on material properties and stator rotor type.

2) PerMix offers special model according to customers' requests.

3) PerMix reserves the right to modify the design without notice.

(3) PT-C/F (Two Pump Design)

| Model | Mixer power, kW | RPM, 50Hz | Self-priming pump, kW | Pump rpm, 50Hz | Max. Liquid Capacity, Tons/hour | Max. powder capacity, Kg/min |

| PT-C/F-120 | 4 | 3,000 | 1.5 | 1,500 | 4 | 15 |

| PT-C/F-140 | 5.5 | 3,000 | 1.5 | 6 | 30 | |

| PT-C/F-165 | 7.5 | 3,000 | 4 | 8 | 50 | |

| PT-C/F-180 | 11 | 3,000 | 4 | 12 | 90 | |

| PT-C/F-200 | 22 | 3,000 | 5.5 | 25 | 140 | |

| PT-C/F-210 | 30 | 3,000 | 7.5 | 30 | 190 |

1) Actual liquid and powder capacity will vary depending on material properties and stator rotor type.

2) PerMix offers special model according to customers' requests.

3) PerMix reserves the right to modify the design without notice.

(4) PCH (Pump Grinder)

See PCH Shear Pump specifications.