PRINCIPLE OF OPERATION:

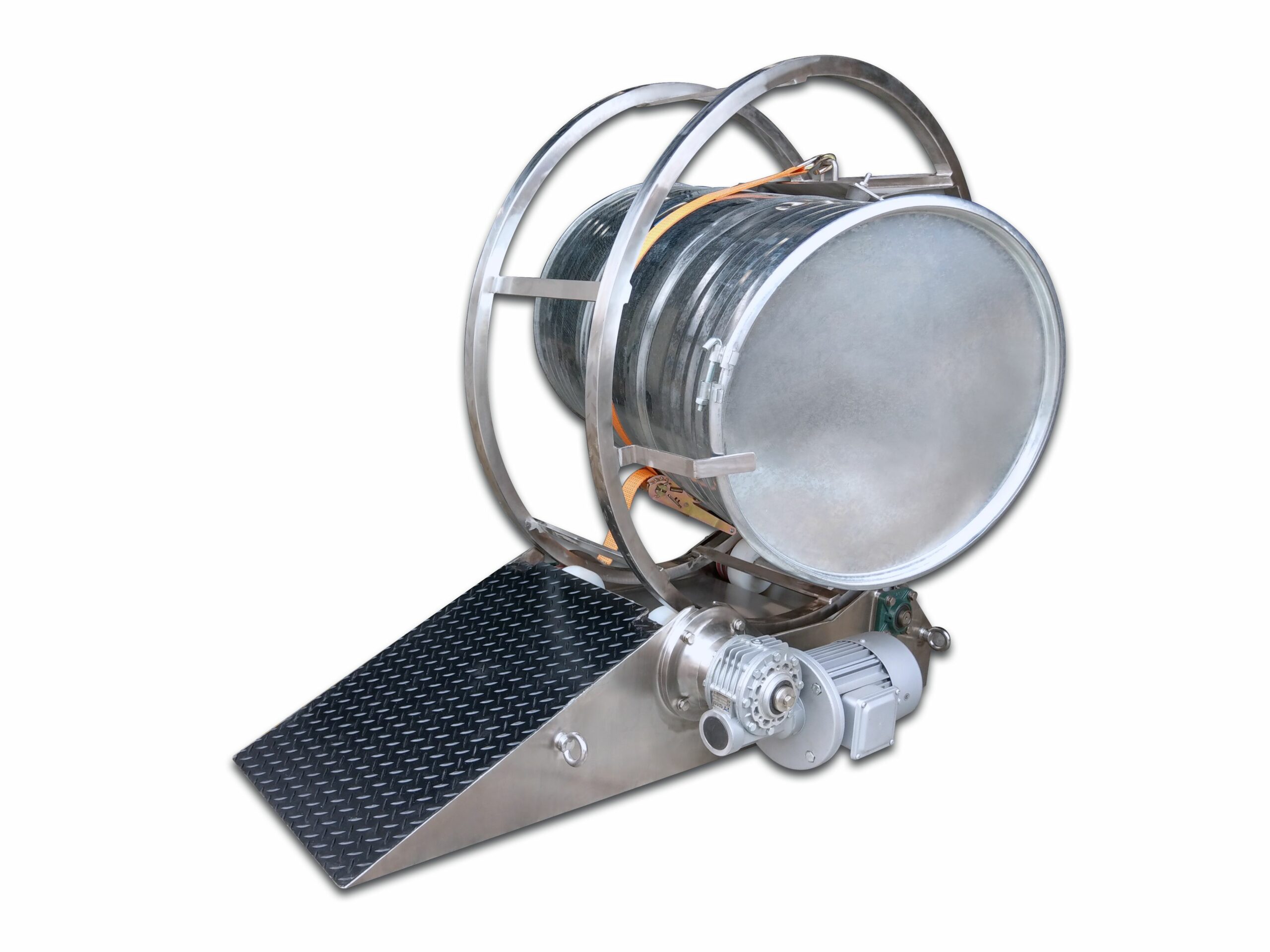

PerMix barrel mixers consist of a motor/gearbox and two shafts with 4 rollers on them. The shafts are attached to the machine frame together with a ramp. The barrel hoop is designed to hold a barrel of powder or granulate. The barrel can be standard sizes with a volume of 50-200 L or can be made to the customer's special needs. The hoop will then be adjusted to fit the barrel tightly and the barrel is attached to the hoop with a strap with two hooks.

To start mixing the barrel mounted to the hoop is turned together manually through the ramp until it settles on the 4 rollers. The drive moves the roller shafts to which it is connected and the two rollers on the shaft start to rotate the hoop/barrel and then the second shaft starts to rotate the remaining two rollers.

The barrel is placed in the hoop at an angle. In this way, the material in the barrel will start to flow up and down, but also to the right and left, which causes the homogenization and mixing of the material after just a few minutes.

ADVANTAGES AND OPTIONS

The advantages of PerMix PDR series barrel mixers compared to traditional mixers are:

- Intensive mixing with the option of equipping with partitions mounted in the barrel

- Suitable for frequent changes of mixed powders, as the barrel, which is usually used for storing the product, can also be used as a mixing barrel

- Prevents improper handling of contaminated or toning products

- The hoop can be used to transport the barrel

- Easy to change mixing container

- Easy to clean mixing container

- Optional GMP execution

APPLICATIONS:

PerMix PDR Series drum mixers are widely used in many applications including:

- Food

Breakfast cereals, enzymes, flavors, herbs, minerals, nutraceuticals, spices, tea blends, tobacco, vitamin blends

Solutions-for-the-food-permix industry

- Chemicals

Agrochemicals, Ceramic Powders, Detergents, Medicines, Dyes, Leather Auxiliaries, Metal Powders, Pigments, Plastic Granulates, Plastic Granules, Plastic Powders, Textile Auxiliaries

Solutions for the chemical industry – Fiprocess

- Pharmaceuticals

Active substances, biological solids, carcinogens, concentrated active ingredients, generic drugs, intermediates, sterile products, toxic substances

Solutions-for-the-pharmaceutical-and-nutraceutical-industry

TECHNICAL CHARACTERISTICS:

| Model | Total capacity (Litres) | Working capacity (Liters) | Max. load (kg) | Power, kW | Rim rotation speed, rpm | Length mm | Width mm | Height mm | Weight kg | |

| PDR-50 | 50 | 35 | 30 | 0.55 | 15 | 1350 | 670 | 1185 | 130 | |

| PDR-100 | 100 | 70 | 60 | 0.55 | 15 | 1350 | 670 | 1185 | 130 | |

| PDR-200 | 200 | 140 | 120 | 0.55 | 15 | 1350 | 670 | 1185 | 130 | |

- The technical characteristics are as accurate as possible but are not binding.

- Length, width, height and weight are given without barrel.

- Special sizes are available upon customer request

- PerMix reserves the right to modify technical characteristics without prior notice.