PRINCIPLE OF OPERATION:

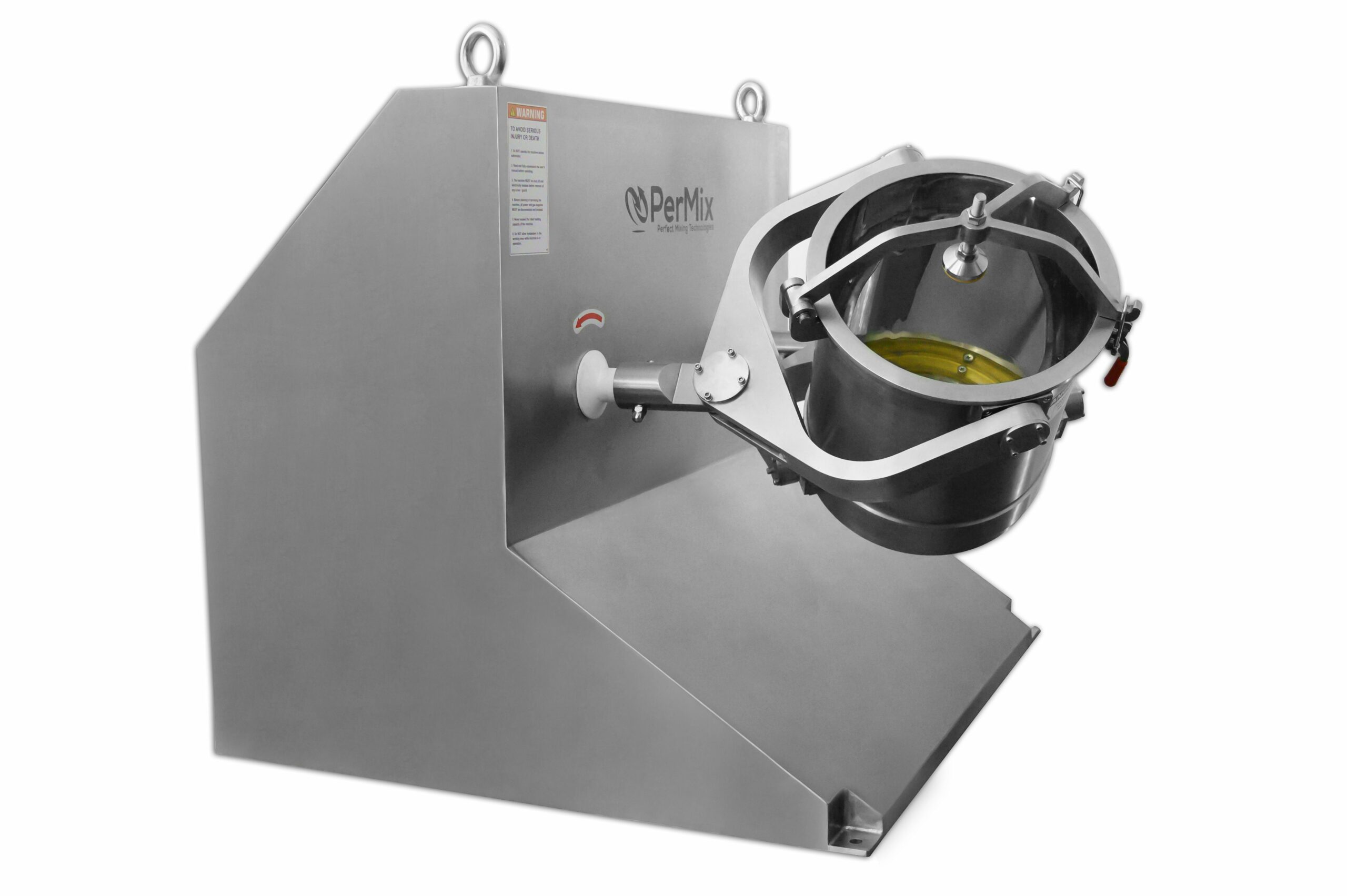

The PerMix 3D mixer consists of a mixing drum that is rotated by two arms, and one arm (the drive arm) is driven by a motor with a belt connection. The other arm, the so-called slave arm, is driven not only to rotate but also to move horizontally. During the mixing operation, the product inside the drum moves in random directions from the center to the end of the trough and simultaneously from the top to the bottom, moving in a multidirectional 3D manner

ADVANTAGES AND OPTIONS

The PTU PerMix series 3D mixer has the following advantages over conventional solutions:

- No cross-contamination thanks to independent containers for different batches when highly hygienic processing is required (for sizes PTU-50 and smaller)

- Interchangeable drums (for size PTU-50 and smaller)

- Complete discharge and easy cleaning

- Perfect mixing uniformity without dead spots

- Sizes from 5 to 300 liters total volume

- Safety barrier to prevent people from getting hurt

- Time saving, quick container replacement, thanks to simple and quick container assembly

- We are able to offer our PTU mixers with a container made of AISI 304, AISI 316 / 316L acid-resistant steel, titanium, Duplex acid-resistant steel, Hastelloy, etc. The standard of internal and external finish can be adjusted to the customer's needs.

SPECIAL DESIGN WITH INTERCHANGEABLE CONTAINERS:

For machine sizes PTU-5, PTU-15 and PTU-50, PerMix offers the option of operating the 3D mixer with interchangeable containers. The container holder is designed to hold the container while being quickly mounted. When the mixer rotates, the container and the container holder are rotated together by two arms.

In addition, containers of different sizes can be accommodated in the same holder with the necessary adapter; for example, the PTU-5 can work with containers ranging from 1L, 2L to 5L.

APPLICATIONS:

The PerMix 3D PTU series mixer can be used in a wide range of processes, including:

- Food

Breakfast cereals, enzymes, flavors, herbs, minerals, nutraceuticals, spices, seasonings, tea blends, tobacco, vitamin blends

Solutions-for-the-food-permix industry

– Chemicals

Agrochemicals, Ceramic Powders, Detergents, Medicines, Dyes, Leather Auxiliaries, Metal Powders, Pigments, Plastic Granulates, Plastic Pellets, Plastic Powders, Textile Auxiliaries

Solutions for the chemical industry – Fiprocess

– Pharmaceuticals

Active substances, biological solids, carcinogens, concentrated active ingredients, generic drugs, semi-finished products, sterile products, toxic substances

TECHNICAL CHARACTERISTICS:

| Model | Total capacity, Liters | Working capacity, Liters | Power, kW | Container rotation speed, rpm | Length mm | Width mm | Height mm | Weight, kg | |

| PTU-5 | 5 | 4 | 0.25 | 28 | 600 | 1000 | 900 | 150 | |

| PTU-15 | 15 | 12 | 0.37 | 20 | 700 | 1000 | 1000 | 200 | |

| PTU-50 | 50 | 40 | 1.5 | 15 | 1120 | 1330 | 1220 | 500 | |

| PTU-100 | 100 | 80 | 2.2 | 12 | 1370 | 1550 | 1430 | 700 | |

| PTU-300 | 300 | 240 | 4 | 8 | 2000 | 2400 | 2100 | 1600 | |

- All specifications are as accurate as possible but are not binding.

- Larger sizes up to 1000L are available on request.

- PerMix reserves the right to modify the design without notice.