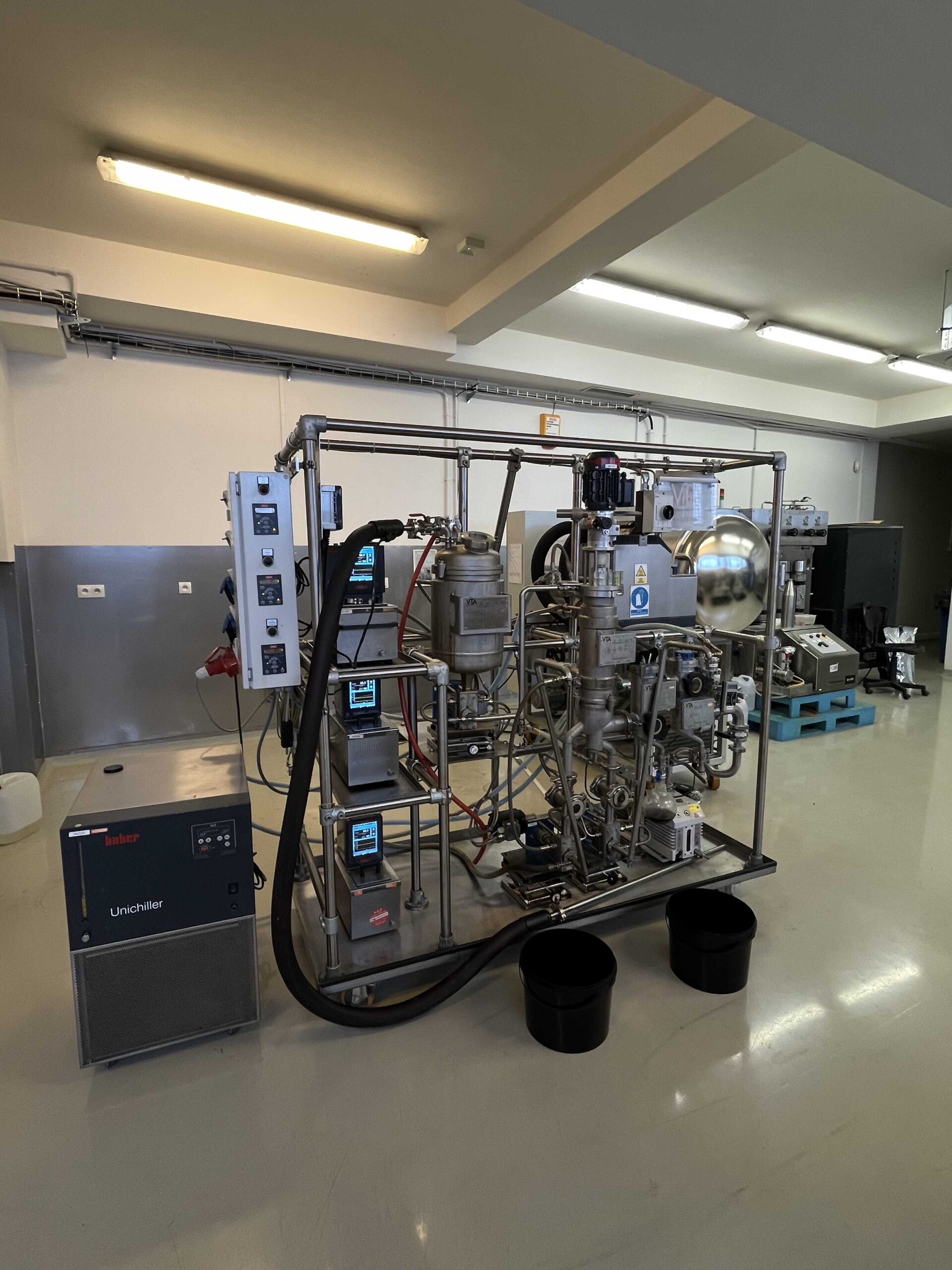

Pilot plant for short path vacuum distillation VTA VK100-10

The VTA VK100-10 vacuum distillation system is an advanced device designed for effective separation of substances under reduced pressure conditions. It is particularly useful in processes requiring gentle treatment of materials sensitive to high temperatures.

Key Features of the VTA VK100-10 Installation:

- Efficiency: The ability to process large volumes of material, making it suitable for industrial applications.

- Precise parameter control: Advanced control system enables precise monitoring and regulation of temperature and pressure, ensuring optimal conditions for the distillation process.

- Safety: Equipped with advanced safety systems, protects against potential hazards associated with working in a vacuum.

- Versatility: Possibility to adjust operating parameters to different types of materials, which makes the installation universal in industrial applications.

The VTA VK100-10 installation is the ideal solution for companies looking for an efficient and safe way to carry out vacuum distillation on an industrial scale.

The VTA VK100-10 Vacuum Distillation Kit includes the following components:

- Distillation column – the main element for carrying out the distillation process.

- Vacuum pump (2x) – to maintain low pressure in the system.

- Evaporator – for heating a liquid and evaporating it.

- Condenser – to condense vapor into liquid.

- Two distillate collection lines – for collecting separated fractions.

- Control system – to monitor and regulate temperature, pressure and flow.

- Valves and fittings – to control the flow of substances in the installation.

Technical data of the distillation unit:

Model VK 100-10

Maximum distillation temperature 300 °C

Minimum achievable operating pressure (depending on product) < 10-3 mbar with rotary vane and oil diffusion vacuum pump,

Capacity 1 – 10 l/h (depending on the product)

Evaporation surface 0.10 m²

Internal condenser area 0.15 m²

Other general data:

- The receivers are made of borosilicate glass

- The evaporator, supply tank, cold traps, wiper basket and rotary gear are

made of acid-resistant steel

- The seals are made of FKM (Viton)

- All glass joints will be made with standard ground or ball ground joints.

- The unit will be equipped with a power distribution system. The customer's power supply will be

400V / 50Hz / 3 phases / loadable neutral / physical grounding.

- All electrical receivers will be marked with the CE mark (European standard).

Standards used: EN (European Standard) and DIN (German Industrial Standard). American standards are not included.

- None of the devices are made in an explosion-proof version

Detailed specification:

Item 1. Power supply

Stainless steel supply tank in jacket construction with flanged cover with spare nozzles: 10 liters

Gear pump in jacket design (design temperature 300°C), pump speed is regulated by frequency converter. Frequency converter is located on the plant platform: max. 14.0 l/h

Supply line to the evaporator in a shell construction

Drain valve (without jacket)

Overflow valve in heated construction

Item 2. Short path distiller VK 100-10

Distiller surface area: 0.10 m²

Internal condenser (beam): 0.15 m²

Material: 1.4571 (316 Ti) or 1.4404 (316L)

Digital wiper speed display with motor drive: Yes

Evaporator temperature: Max. 300 °C

Working pressure (depending on product): 0.001 mbar

Jacketed design residue nozzle: Yes

Distillate nozzle in a heated design: Yes

Item 3. Discharge of distillate and residue (each)

Visor with coat

Gear pump in jacket design: Max. 14.0 l/h (design temperature 300°C), pump speed is regulated by a frequency converter. The frequency converter is located on the frame of the plant

Discharge siphon downstream of the gear pump in a jacketed design (used as a pressure lock against the atmosphere).

Item 4. Vacuum system

Flanged liquid cooling extruder with receiver in glass (1 liter)

Flange extruder for liquid N2 or dry ice with receiver in glass (1 liter)

Diffusion vacuum pump for achieving stable vacuum conditions at low pressures: 40 l/s

Two-stage vane pump with exhaust filter: 16.0 m³/h

Vacuum pump equipped with a vacuum pump oil dosing valve for pressure regulation

and venting

1 vacuum measuring device with one manometer.

Digital display.

Measuring range 0.0005 mbar - 1300 mbar

All necessary connecting pipes or hoses for the vacuum system

Item 5. Heating and cooling

Heating unit

1 independent heating unit for – evaporator jacket

Circulation thermostat with digital temperature control and numerical display, including circulation pump

Temperature range: 300°C

Power: 3 kW

Medium (not included in the scope of delivery): thermal oil

The system will be equipped with all necessary connecting hoses (thermal insulating pipes made of acid-resistant steel) for connection to the unit.

Heating unit

1 independent heating unit for – residue line

Circulation thermostat with digital temperature control and numerical display, including circulation pump

Temperature range: 200 degrees Celsius

Power: 2 kW

Medium (not included in the scope of delivery): thermal oil

The system will be equipped with all necessary connecting hoses (thermal insulating stainless steel pipes) for connection to the unit. All necessary jumpers in the heated lines are also included.

Heating unit

1 independent heating unit for – supply line

Circulation thermostat with digital temperature control and numerical display, including circulation pump

Temperature range: 200 degrees Celsius

Power: 2 kW

Medium (not included in the scope of delivery): thermal oil

The system will be equipped with all necessary connecting hoses (thermal insulating stainless steel pipes) for connection to the unit. All necessary jumpers in the heated lines are also included.

Cooling unit (located next to the base)

1 independent cooling unit for – internal condenser and distillate outlet line

Circulation thermostat with digital temperature control and numerical display, including a circulation pump connected to cooling or tap water

Temperature range (nominal value): -10 … 100 °C 2 Heating power: 2.2 kW

Cooling power @ 15°C: 2.2 kW

Medium (not included in delivery): depending on temperature

The system will be equipped with all necessary connecting hoses (thermal insulating stainless steel pipes) for connection to the unit. The set also includes all necessary jumpers in the heated lines.

Cooling unit

1 independent cooling unit for – cold trap

Circulation thermostat with digital temperature control and numerical display, including a circulation pump connected to cooling or tap water

Temperature range (nominal value): -40 … 200 °C

Heating power: 2 kW

Cooling power at 0°C: 0.38 kW

Cooling power at -20°C: 0.25 kW

Medium (not included in delivery): Depending on the temperature

The system is equipped with all necessary connecting hoses (thermally insulated stainless steel pipes) for connection to the device. All necessary jumpers in the heated lines are also included in the set.

Item 6. Frame, connectors

Frame made of stainless steel pipes (DN 32) with connection clamps for variable use. It is equipped with 4 wheels and is mobile. A tray for collecting leaking liquid is included.

Item 7. Power supply to the power distribution system (by the customer)

Voltage: 400V

Frequency: 50 Hz

Number of phases: 3

Included Power Distribution System: Yes

Frequency inverters located in the assembly station: Yes