Animation of a rotating screen

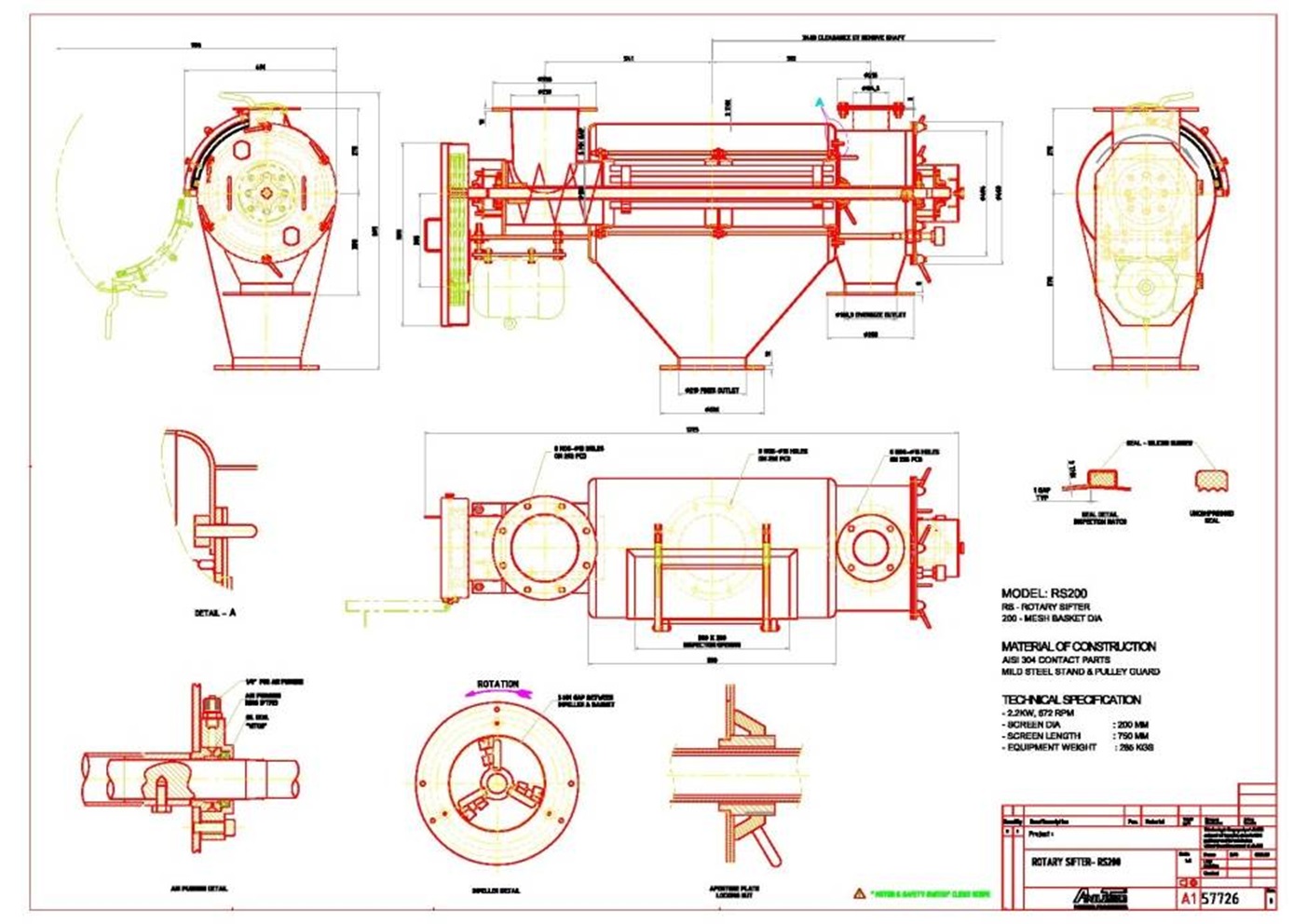

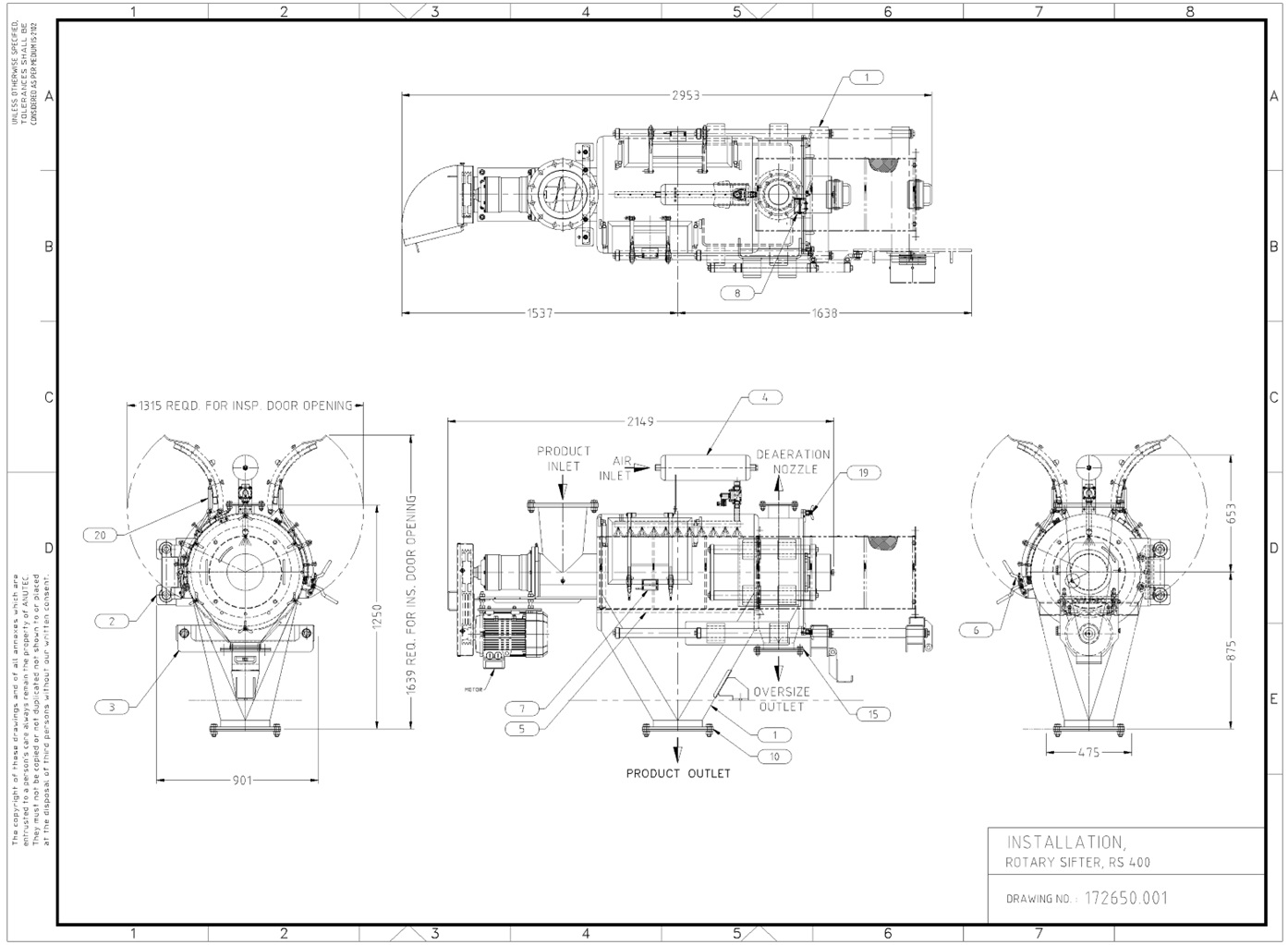

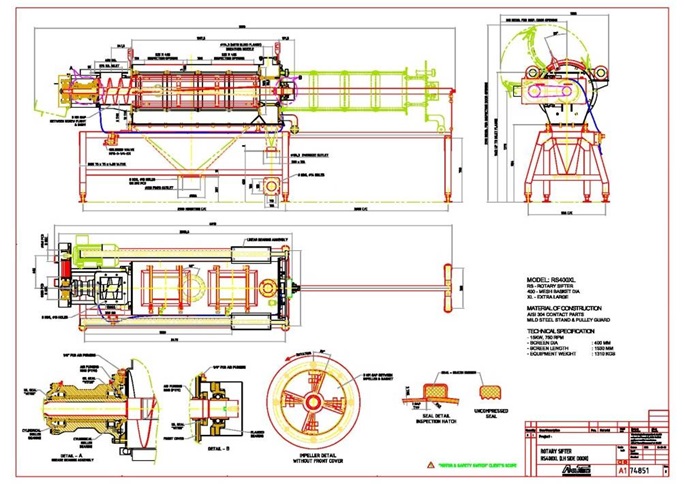

Dimensions

| Model | Engine power | AND | B | C | D | E |

| RS200 | 2.2kW | 541 | 513 | 1720 | 845 | 555 |

| RS300 | 3.7kW | 641 | 563 | 1885 | 875 | 620 |

| RS400 | 5.5kW | 641 | 563 | 1895 | 945 | 745 |

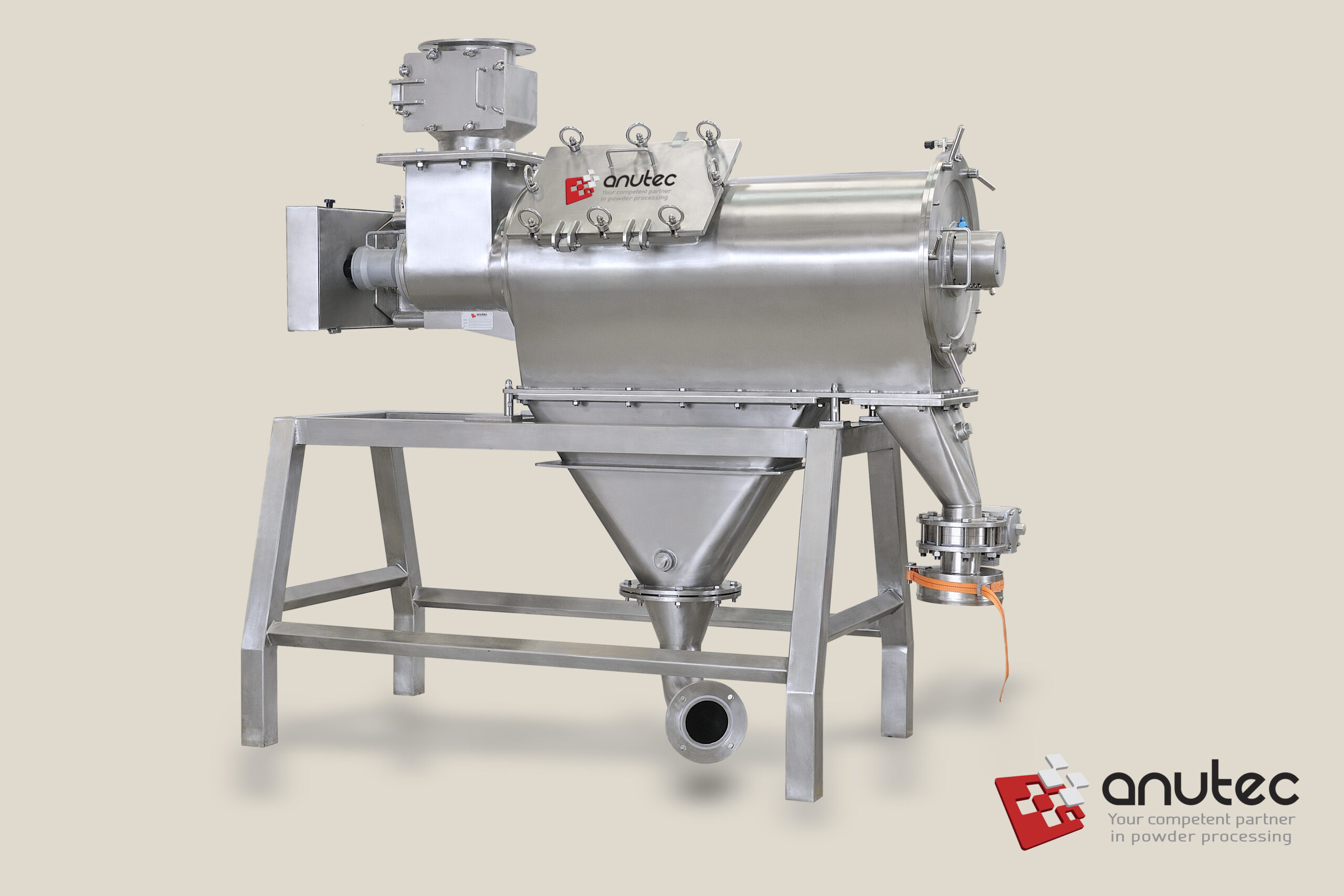

Execution

The units are available in mild steel, V2A and V4A (304 and 316 stainless steel) and in various configurations, allowing for customization to individual requirements. Screen meshes can be supplied in stainless steel or nylon, with different mesh sizes, depending on customer needs and product specifications.

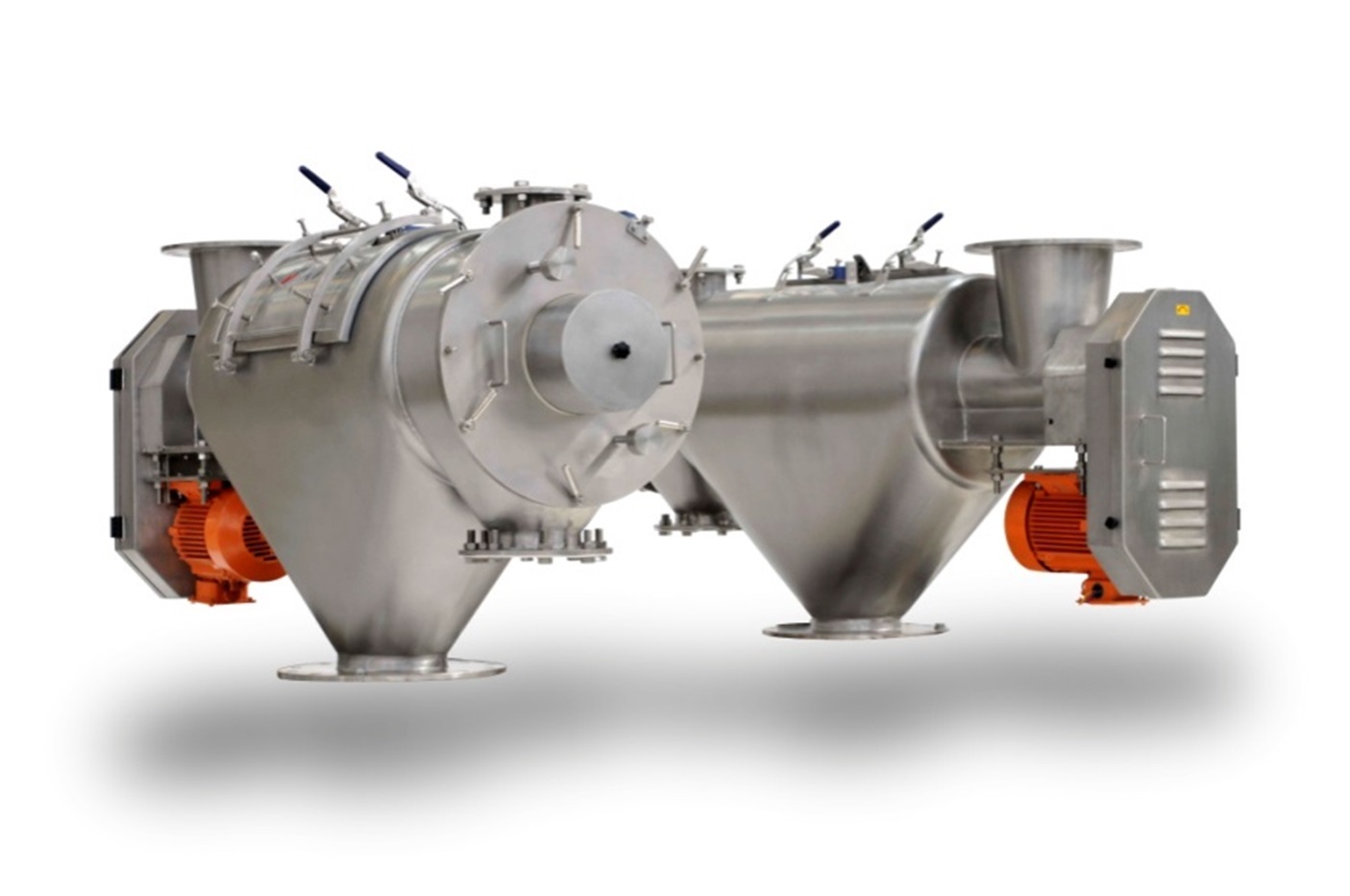

Rotary screen for production line control and protection

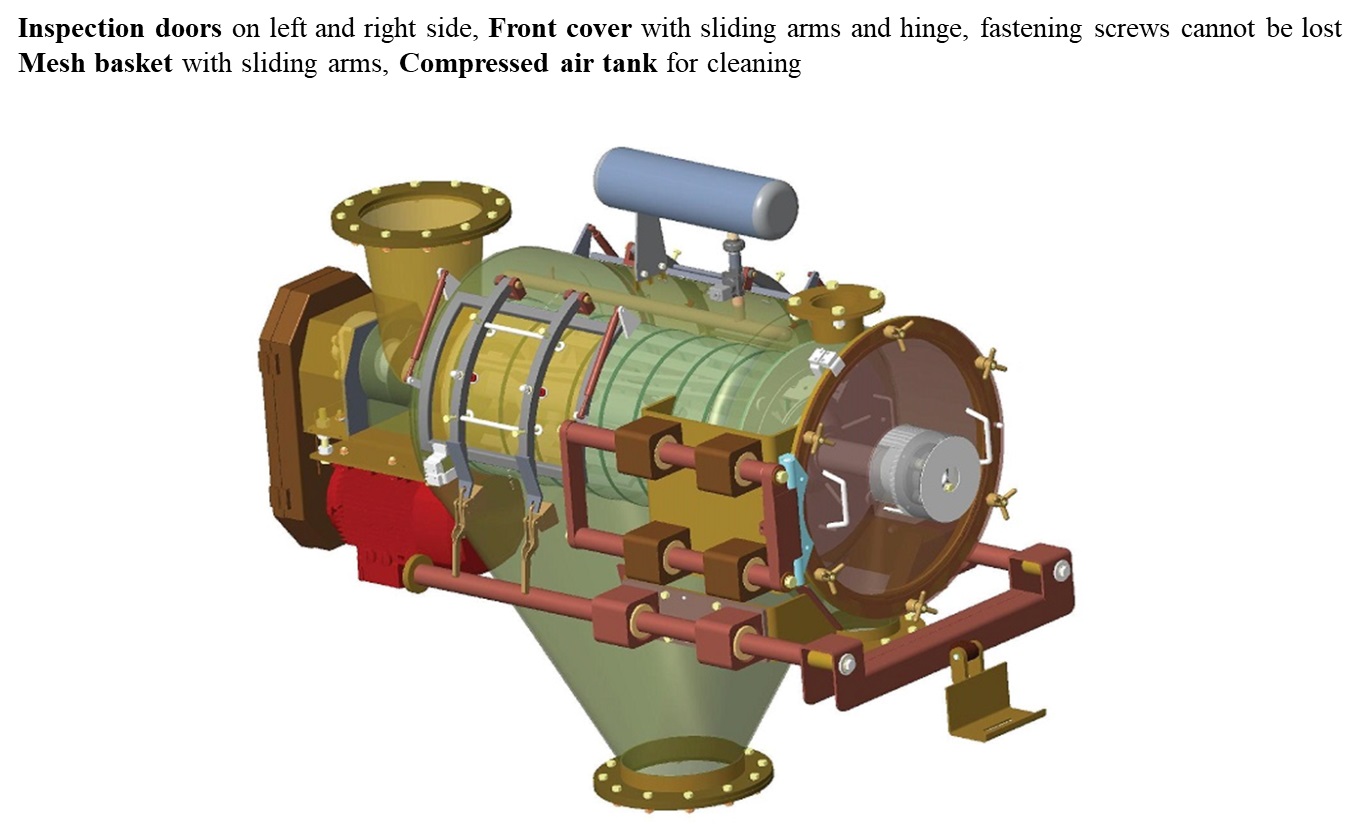

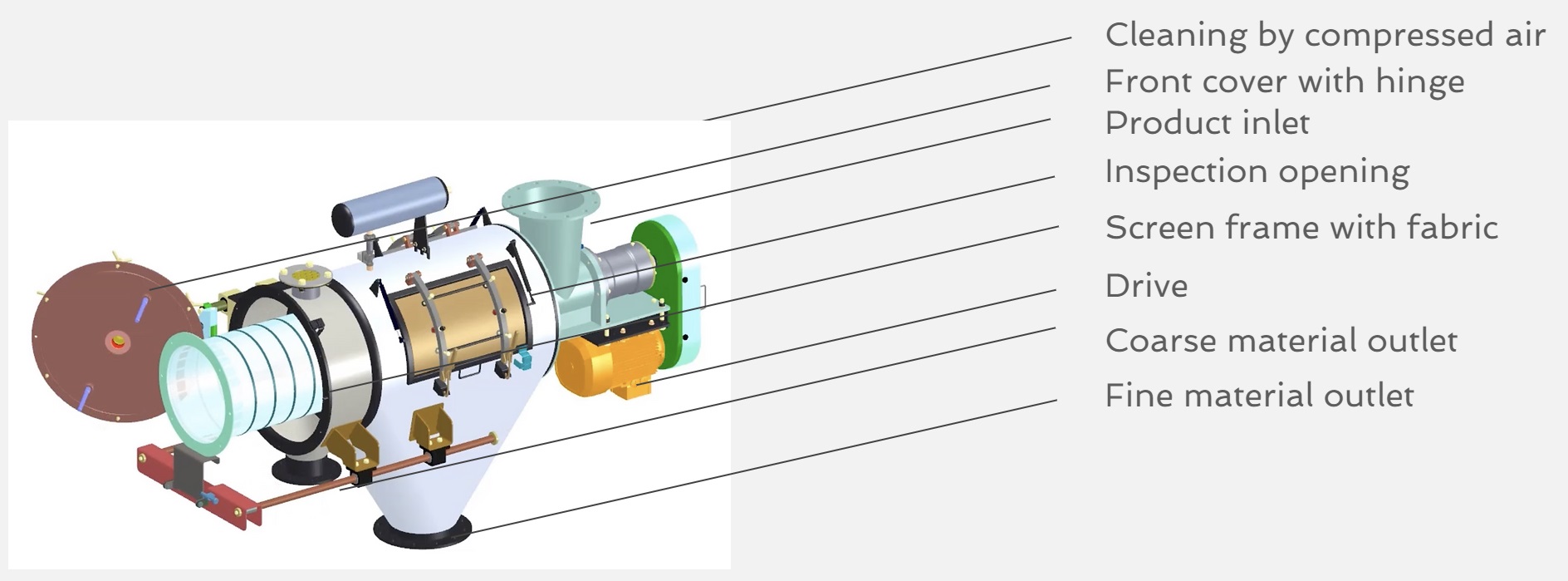

Material is fed into the cylindrical screening chamber by a feeding screw, which is conveyed to a rotating spiral blade.

Centrifugal force accelerates the particles relative to the screen. Rotating blades, which are not in contact with the screen, break up soft agglomerates and push individual particles through the screen while rejecting hard lumps and debris.

The screen is attached to the carrier basket in such a way that it can vibrate freely. This method of suspension also provides the screen with elasticity, which allows it to safely absorb significant impacts from foreign material

Application

For all processes that must prevent contamination of the product with agglomerates and/or foreign particles.

The devices are suitable for the food, pharmaceutical, chemical and synthetic materials industries.