DESIGN FEATURES:

In addition to the standard features of the PerMix High Speed disperser, such as hopper clamp arms, hydraulic lifting station, full set of safety switches, variable speed control etc., PerMix can also customize accessories to suit your specific needs, these options include but are not limited to:

- Rotating head that can handle several stationary tanks

- Quick-release vacuum lid for easy removal

- Adjustable splash and dust cover

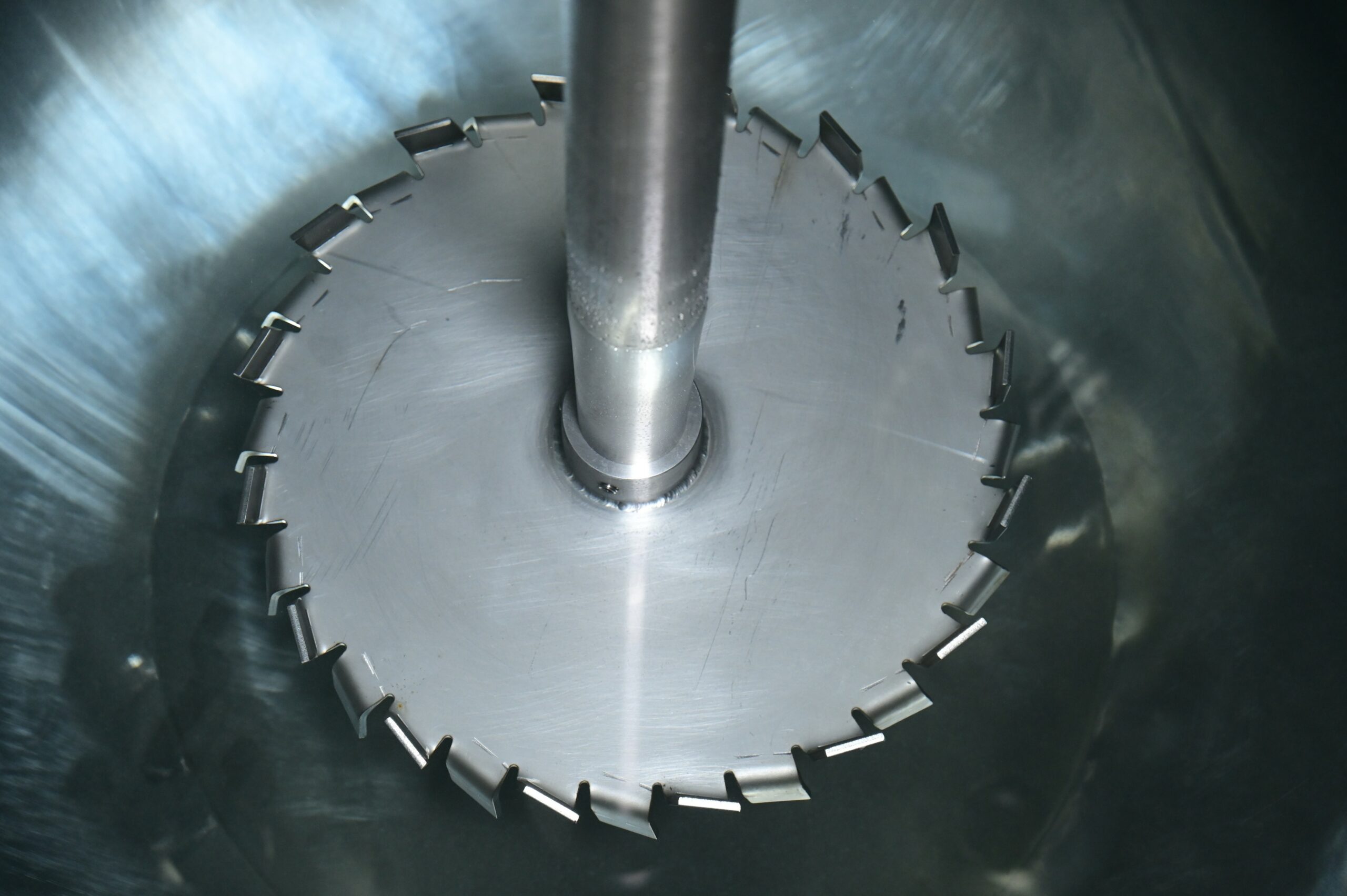

- Static gear ring rotor system for very high shear forces

- Mixing tanks

- Double-shell tanks

- Individually driven scrapers

SPECIAL PROJECTS:

PerMix stands out from other suppliers by being able to supply our PD series high-speed dispersers in special designs for specific purposes:

– The PerMix High-Shear Laboratory Disperser (Dissolver) is used for research and development purposes, performing each of the previously mentioned functions.

– The PerMix High Speed Vacuum Disperser (Dissolver) creates a high-intensity motion that quickly removes air or gases from the product. The built-in vacuum cover lifter allows the height of the dissolver disk to be adjusted without interrupting the vacuum.

– PerMix High-Speed Twin Shaft Disperser (Dissolver): The unique combination of a slow-running element and a high-speed dissolver disk produces batches of excellent quality and uniformity that are twice as large as those produced by a conventional system. This mixer can handle products with high viscosity (up to 600,000 cP) or high solids.

– A vacuum version of the PerMix high-speed disperser (Dissolver) is also available, as well as various types of low-speed elements.

– The PerMix WALL-MOUNTED high-speed disperser (Dissolver) is a practical and economical way to produce small and medium-sized batches. The counterweight helps to lift the mixer, which can then be locked in any desired position. Optionally, the lifting system can be controlled manually, electromechanically or hydraulically.

APPLICATION:

The most popular and common applications of PerMix high-speed dispersers are:

– General: dispersing, suspending, emulsifying, dissolving, homogenizing, mixing and breaking up agglomerates of high viscosity materials (up to 300,000 cP)

– Paints, varnishes and printing inks: Preparation of batches of paints, tracing paints, artist’s paints, primers and derusting paints, fillers, dispersion and coating paints, varnish pastes, printing inks, resin solutions, textile printing inks, etc.

– Plastics: Preparation of all types of PVC, PU pastes, color concentrates and putties for plastics

– Adhesives: Preparation of rubber, neoprene, resin and other types of adhesives

– Chemistry: preparation of dispersions of fillers, coating materials, insulating materials, bitumen-based sealing materials, lubricants and greases

TECHNICAL CHARACTERISTICS:

| Model | Working capacity (litres) | Main engine (kW) | Maximum shaft speed (rpm) | Overall dimensions | Weight (kg) | ||||

| D (mm) | W (mm) | In (mm) | W (tilting version) (mm) | Disc diameter (mm) | |||||

| PD-5L * | 2-5 | 0.55 | 0-10,000 | 460 | 420 | 740 | 990 | 50/60 | 30 |

| PD-70 * | 70 | 1.5/2.2 | 3,000 | 680 | 775 | 1410 | 1910 | 120/100 | 140 |

| PD-100 | 100 | 3 | 2,100 | 950 | 400 | 1500 | 2100 | 150/100 | 200 |

| PD-200 | 200 | 5.5 | 2,100 | 1400 | 700 | 1750 | 2550 | 200/150 | 500 |

| PD-300 | 300 | 7.5 | 2,100 | 2200 | 1100 | 2100 | 3100 | 250/200 | 1200 |

| PD-500 | 500 | 11 | 1,500 | 2200 | 1100 | 2100 | 3100 | 300/250 | 1300 |

| PD-700 | 700 | 18.5 | 1,500 | 2400 | 1300 | 2200 | 3300 | 350/300 | 1400 |

| PD-1000 | 1000 | 22 | 1,500 | 2500 | 1400 | 2200 | 3300 | 400/300 | 1600 |

| PD-1200 | 1200 | 30 | 1,500 | 2800 | 1600 | 2500 | 3700 | 425/350 | 1900 |

| PD-2000 | 2000 | 37 | 1,500 | 2800 | 1600 | 2500 | 3700 | 500/425 | 2100 |

| PD-3000 | 3000 | 55 | 1,500 | 3400 | 2200 | 3000 | 4500 | 625/500 | 2400 |

| PD-4000 | 4000 | 75 | 1,000 | 3400 | 2200 | 3000 | 4500 | 700/625 | 2600 |

| PD-6000 | 6000 | 110 | 1,000 | 3800 | 2400 | 3200 | 4800 | 800/700 | 3100 |

1) The PD-5L/PD-70 dimension/weight information includes the manual lifting mechanism.

2) Specific working capacities can be offered as per customer requirements.

3) All specifications and illustrations are as accurate as reasonably possible but are not binding.

4) PerMix reserves the right to modify the design without notice.

PerMix PD High Speed Dispersion Mixer Brochure