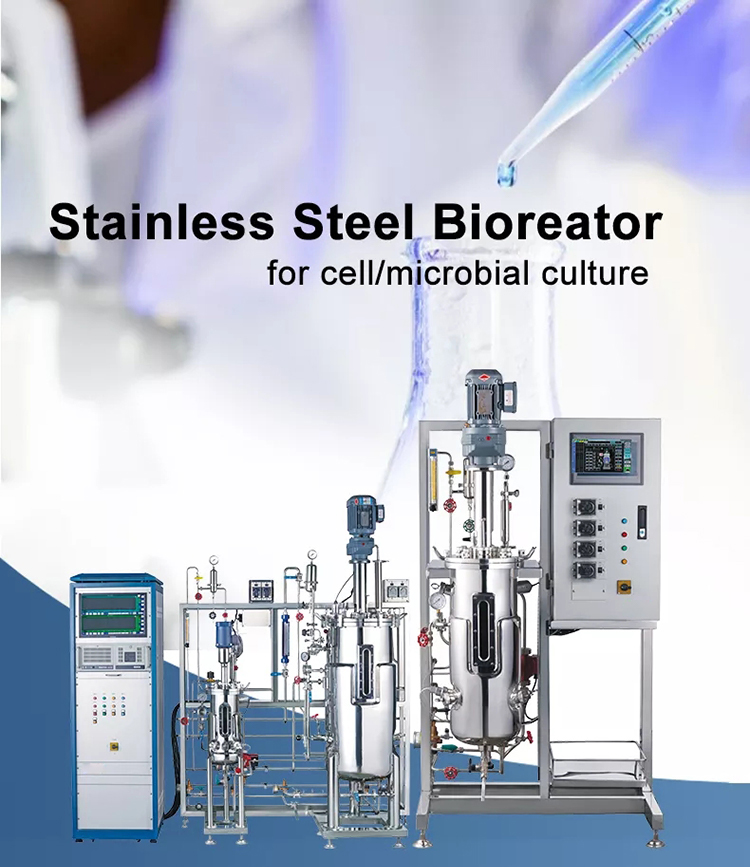

Technology description

Bioreactor, fermenter, fermenter – a device enabling the carrying out of processes microbiological, enzymaticas well as cell cultures multicellular organisms, designed to enable process management through measurement and parameter regulation, production process control, and optimal execution, while minimizing or completely eliminating the possibility of contamination. The device enables monitoring and regulation of process parameters, such as temperature and aeration, ensuring optimal microbiological and enzymatic processes. Bioreactors are used in biotechnology, pharmacy, the food industry, and biogas production.

Bioreactors, or biofermenters, are reaction vessels in which all processes, i.e., chemical and biochemical reactions, take place to transform a substrate into the desired end product. Reactions can occur in a bioreactor thanks to the presence of biocatalysts, i.e., enzymes isolated from microorganisms, or the microorganisms themselves, animal or plant cells, or parts thereof.

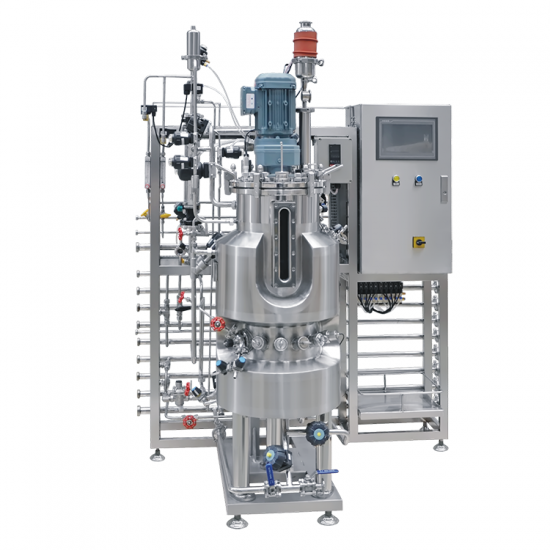

Key features and functions:

- Controlled environment:

Provides stable conditions for the growth of microorganisms, eliminating the risk of infections.

- Sterility:

Many bioreactors are designed to maintain process sterility.

- Parameter adjustment:

It allows you to measure and control key factors such as temperature, aeration and pH, which optimizes the production process.

- Mixing and aeration:

Built-in mixers and aerators ensure even distribution of nutrients and oxygen in the medium.

- Scale:

Bioreactors are available on both laboratory and industrial scales.

Areas of application:

Catalyst evaluation and hydrogenation

Synthesis of polymers and advanced materials

Fine chemicals and pharmaceutical intermediates

Studies of gas-liquid reactions and multiphase reactions

Production processes of hydrolysis, neutralization, crystallization, distillation, evaporation and other processes in medicine, chemical, food and light industry

Chemical reactions such as hydrogenation, oxidation, alkylation, chlorination, carboxylation, nitration, polymerization, transamination, bromination, ethoxylation, esterification, sulfonation, etc.

Crystallization, concentration, distillation, reflux, separation and purification – the ideal tool for processing crude oil

Ideal for applications in chemical synthesis, pharmaceutical research and development, materials science, catalyst evaluation, and hydrogenation experiments

Mixing reactions of liquids and other chemical media, strong oil penetration. Chemical synthesis. Organic synthesis, polymer polymerization. Food technology in vulcanization. Fluoride. Areas covered include: beverages, flavors and dyes, dairy and egg products, plant and vegetable extracts, pharmaceuticals, heat-sensitive synthetic materials, plastics, polymers and resins, perfumes, blood, ceramics and superconductors, biochemicals, dyes, soaps and detergents, food products, adhesives, oxides, textiles, bones, teeth and dental amalgams, and many others.

Equipment:

Construction material: stainless steel 304, 316, 316L, Hastelloy, titanium (optional)

Optional PTFE or stainless steel stirrer

Sealing method: magnetic clutch, tight

Heating method: electric heating jacket / oil bath circulation

Dedicated exhaust and air inlet ports for easy sampling, product discharge, and gas introduction

Safety devices: pressure gauge, safety valve, bursting disc, temperature controller,

Other sensors depending on the process

Made in accordance with cGMP standards with validation (FAT, SAT, IQ, OQ)

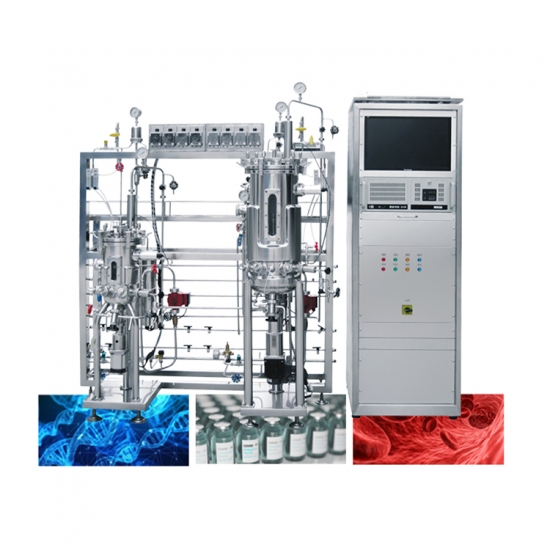

Additional configurations

The ability to custom configure features such as a tank lid lifter, four-valve sanitation unit, CIP or SIP system, flue gas analyzer/mass spectrometer, biochemical analyzer, etc., allows us to provide personalized products for customers with diverse needs, improving equipment automation, intelligence, and user comfort.

Certification and approvals:

CE

ATEX

PED or ASME

Material certificates

Example capacities:

Bioreactors are designed to meet the customer's product and process requirements. Each project is treated individually, after determining a number of technical parameters.

Example capacities:

– micro reactor 10ml-500ml

– laboratory scale 1, 2, 3, 5, 10, 20, 30 L

– industrial scale 50, 100, 150, 200, 500 L

– other capacities on request