Easy validation of the mixing process with PerMix

PerMix revolutionizes the validation process and the need to improve mixing technology.

One of the biggest problems we face as producers of food and pharmaceutical products is the need to validate new process technologies, which makes it difficult for us to change and develop. This is no longer a problem. PerMix has created a 4-in-1 mixer that allows you to change the type of mixer in a matter of seconds. This means validation is now easier than ever.

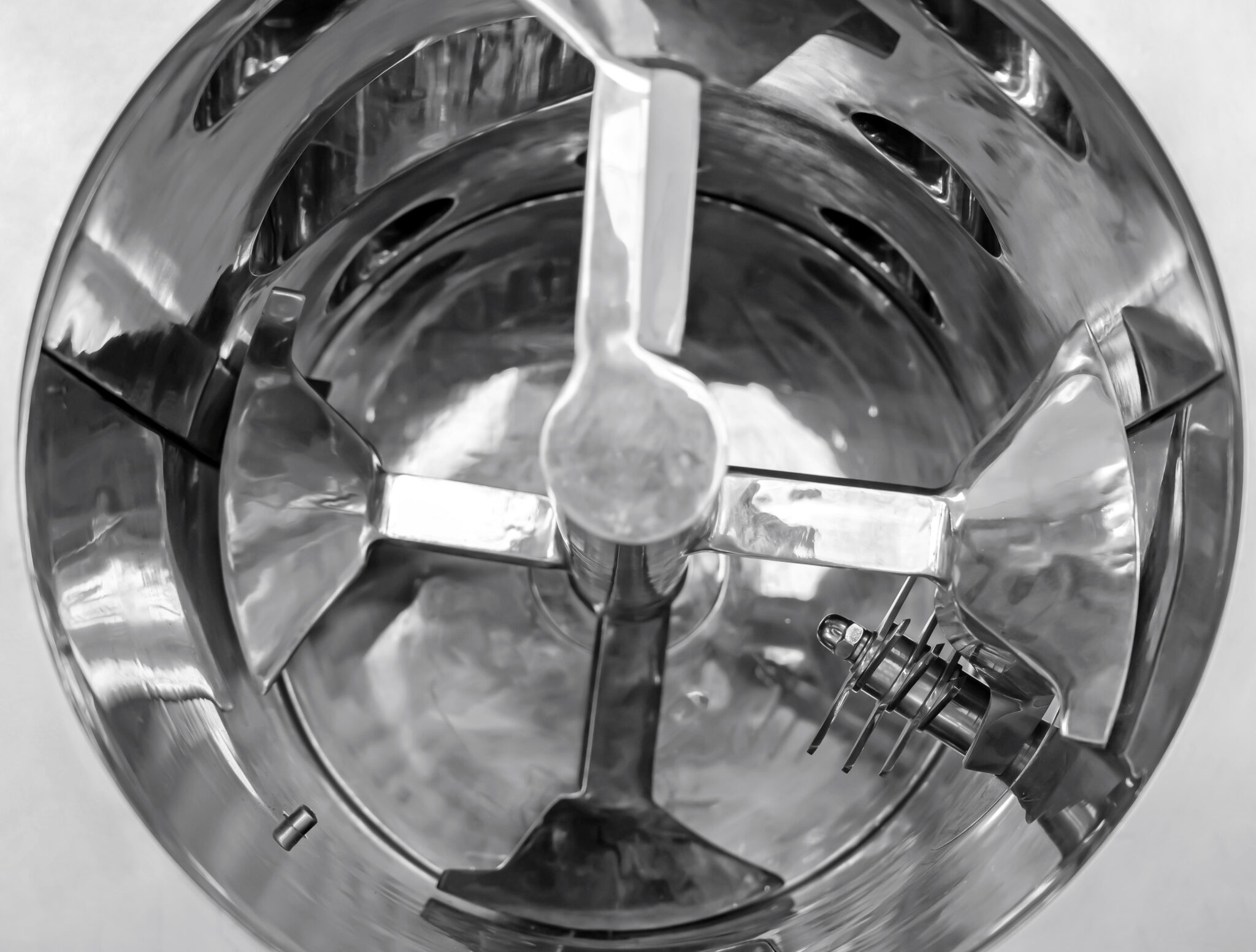

PerMix 4 in 1 mixer presented at POWTECH - ribbon mixer, paddle mixer, blade mixer and vacuum mixer/dryer in one machine.

Simply select the currently installed mixer type, enter the process parameters and start the process. Then save the parameters and change the mixer type to the new one you want to test, adapting to the time and performance of the new mixer. Start a new cycle. Data logging covers the entire process of the previous process and the new one and then compares them. Nothing easier. Take LEAN manufacturing or any other process change to the next level of ease with PerMix.

The 4-in-1 unit allows R&D departments to switch between 4 different types of mixers that can potentially be used in the production process. With the ability to switch between ribbon mixer, paddle mixer, blade mixer and fluidized zone mixer, the system is essential in multi-plant production of food, pharmaceuticals, nutraceuticals, chemicals and more. Thanks to the possibility of mixing in a vacuum atmosphere, as well as heating and cooling, all controlled by PLC/HMI, the device is the best tool in the world of processing.

With data capture and recipe control, you take the guesswork out of scaling. Save space, save utilities, and save on the cost of purchasing additional machines by having one machine that can do it all. Only from PerMix.