MAIN ADVANTAGES:

EASE OF USE

- No leaks.

- Parts may be dry to the touch.

- Simple operation.

CONFIGURABLE

- Control of consumption of the product used.

- Deposition of the product over the entire surface.

- Fully automatic cycle.

- Guaranteed repeatability.

- Possibility of gas-tight construction.

OPTIMIZATION

- Recycling the product used.

- Guaranteed contamination-free and clean deposition.

- No aerosol.

MAIN FEATURES

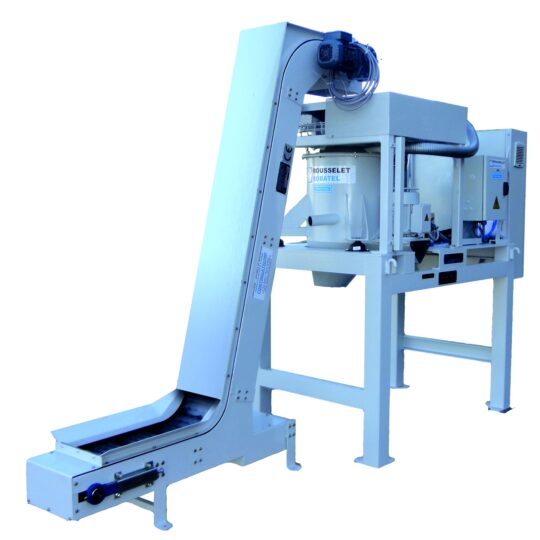

- Conical support bowl, mounted on the spindle, designed to accommodate a removable basket that can be tipped over to unload parts (handles or pins for manual handling).

- Suspended at 3 points (SA/SC type) or rigid (RC type).

- Driven by an axial motor (SA type) or a side mounted motor (RC/SC type), connected to a frequency inverter to regulate the rotation speed.

- Product tank and recycling tank with pump, strainer in outlet area, filling and emptying caps, low level sensor and visual level, inspection cap, etc.

- Fully automatic cycle; ability to set the duration of the static coating and dewatering via the pump operating time

- The rotation speed can be set using the potentiometer (10 to 100% maximum speed).

- Independent control/control panel with switches and lighting.

- Security features compliant with US and EU standards.

- Materials: Mild steel, Viton seal for cover, Nitrile rubber, various materials for other seals and components…

TYPICAL CYCLE OPERATION

1- Installing the removable basket in the centrifuge, loaded with parts.

2- Closing the cover.

3- Automatic cycle.

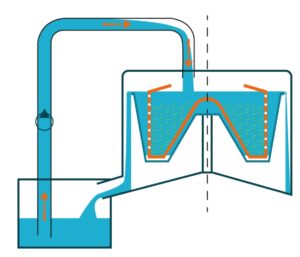

COATING PHASE

- The coating pan is supplied with liquid pumped from a tank.

- The pump stops once the part is immersed and static coating begins.

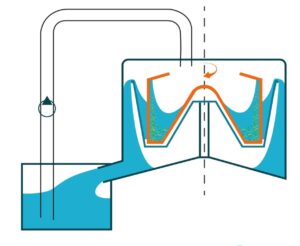

DEHYDRATION PHASE

- The rotational speed of the bowl + basket system is gradually increased, allowing the liquid to flow back into the tank.

- Dewatering at a given speed and for a given time so that a thin layer remains on the surface of the part.

- Optional drying with hot air heating system.

- Slow down to a complete stop and unlock the cover.

- Opening cover.

- Removing the basket to unload parts.

OPTIONAL EQUIPMENT AND AUXILIARY DEVICES

- Materials: stainless steel, hydrophobic coating (Halar, Rilsan, cothal, etc.).

- Tank: fine particulate filtration system guaranteeing a clean coating, filter clogging detector, sealing level (reinforced, pressurized, etc.).

- Basket: special perforations, suitable filter elements (removable bag), non-removable basket, basket with conical bottom (in combination with an inverting mechanism for parts with large retention surfaces), lower outlet basket (for massive parts), basket with compartments, basket with flat bottom, etc.

- Cover: spring or pneumatic assist, manual lifting, fume extraction system, etc.

- Controls: pre-programmed cycles (automatic or cycle-by-cycle), fume control integration or fume traceability.

- Other versions: explosion-proof version (RC/SC types), vacuum version, automated version, etc.

- Peripherals: independent heating system (type C2), temperature control system, support with lifter, additional removable basket, liquid discharge nozzle mounted on the cover, retention tank, etc.

TECHNICAL CHARACTERISTICS OF IMP MODELS

| Bin | Bin | Bin | Bin | Bin | Bin | |||

| Model | Diameter mm | Usable capacity L | Capacity L | Capacity L | Max. Load kg | Weight kg | Bowl capacity kg | Maximum speed rpm |

| SA 40 Vx KC IMP | 300 | 180 | 15 | 8 | 25 | 8 | 22 | 1000 |

| SA 50 Vx KC IMP | 475 | 280 | 40 | 30 | 60 | 11 | 60 | 1000 |

| RC 50 Vx KC IMP | 475 | 280 | 40 | 30 | 60 | 11 | 60 | 1000 |

| SC 70 Vx KC IMP | 645 | 330 | 80 | 50 | 100 | 40 | 160 | 900 |

| SC 85 Vx KC IMP | 790 | 380 | 155 | 90 | 180 | 53 | 240 | 750 |